Silicone is a unique material: soft, elastic, yet durable and can withstand strong heat and prolonged freezing. He goes to the manufacture of various products, including the most diverse forms. At home, you can make molds of sealant with your own hands: the main thing is to choose a product with the right composition - based on silicone.

- Application area

- Silicone mold making

- Materials and Tools

- Component Mixing

- Mold casting

- Using Sealant - The Second Method

- Precautionary measures

Application area

Silicone is an organosilicon compound that is actively used in many areas of human life. The substance is especially popular in construction and repair, since on its basis the following are performed:

- sealants;

- adhesive lubricants;

- water repellent impregnation;

- primers;

- defoamers;

- adhesives;

- compounds, etc.

Cooking molds for baking, freezing and storage are cast from silicone. Silicone molds are widely used for the manufacture of jewelry, figurines, various items of decor and creativity. Products from this elastomer are used in the automotive industry and even in medicine, because it is hypoallergenic, non-toxic and completely safe for health.

to contents ↑Bioinert silicone, does not react with surrounding surfaces, does not provoke metal corrosion, can be used at extreme temperatures, in damp rooms and in direct contact with water, chemicals.

Silicone mold making

Silicone molds are presented in stores in a large assortment, and yet it is not always possible to choose the appropriate option. Many craftsmen prefer to make molds on their own in order to reduce costs and get a really needed product. You can create forms in various ways, including using silicone sealant.

to contents ↑Materials and Tools

To make molds, you need to prepare such devices and consumables:

- the catalyst is 2.5 mg (white spirit is suitable);

- silicone sealant of good quality - 100 ml;

- acrylic paint - the right amount;

- glycerin - 10 drops;

- a plastic cup;

- spoon and dropper;

- container;

- sand;

- blank for the mold;

- vegetable oil or soap;

- tassel.

Component Mixing

First you need to connect all the liquid components together. Put the sealant in a plastic cup, add glycerin and paint, using a pipette. Mix the mass well, pour the white spirit. After mixing the composition until it becomes homogeneous.

to contents ↑Mold casting

After combining all these components, a composition is obtained that is well suited for casting of any form. Adding a solvent can reduce the rate of hardening of silicone and have time to perform further necessary actions with it.

The procedure for subsequent work is as follows:

- take any container or other container without holes;

- put in a container a model of the future form, which was previously molded from gypsum, polymer clay, plasticine or other improvised means (usually a suitable product is pasted over with such materials, then the convex master model is carefully disconnected);

- fill the workpiece with sand in order to accurately calculate the amount of silicone solution required;

- pour sand, grease the master model with oil or soap, fix in a container;

- apply silicone to the mold, carefully working out the smallest bends of the relief, allow the material to dry;

- after 5-10 minutes, fill the remaining silicone;

- after 8-10 hours, disconnect the finished form from the master model.

Using Sealant - The Second Method

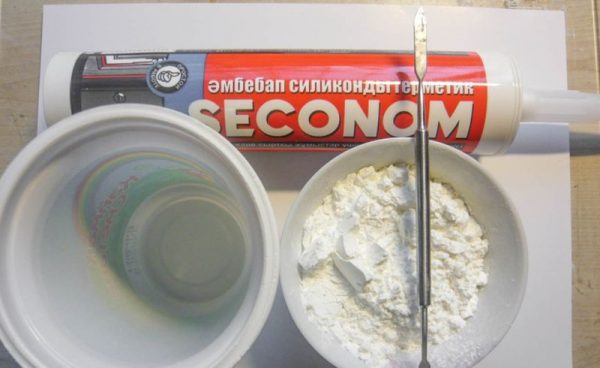

There is another way to make molds from silicone, however, with their help they turn out to be less elegant, and small details are not always clearly visible. In its pure form, the sealant is quite sticky, so you need to introduce potato or corn starch into it. The proportions must be selected so that in the end we get a thick "dough". The sealant should be put in a disposable glass, adding a little starch and preparing the mass.

After kneading the dough, you need to take the master model, grease with cream or oil, then stick silicone around. Leave the workpiece for a day, then disconnect from the base. Another option is to press the master model into the ball of dough, carefully align the edges, and after a couple of minutes get the product.

to contents ↑

Precautionary measures

Silicone itself is not a toxic substance, but the solvent in the process emits harmful fumes to the body, so all manipulations should only be done:

- in rubber gloves;

- with open window or forced ventilation.

The ideal option is to practice pouring molds on the street or on the balcony, loggia. This work is very exciting and allows you to create the most unique models, realize any ideas, without spending extra money!