Laminate is a practical and durable floor covering. Unlike parquet, it is inexpensive, although the most durable and wear-resistant options have a higher price. Of course, this floor covering also has disadvantages, and one of them is insufficient water resistance. To minimize negative qualities, you can use a special sealant for the laminate.

- Why sealant is needed

- Sealant composition

- Properties and characteristics of the sealant for the laminate

- Types of compositions for processing laminate locks

- Laminate Sealant Gel

- Silicone sealants

- Acrylic Sealants

- Most popular brands

- Click guard

- Click protect

- Soudal

- Roci aquastop

- Masterfix

- Quick step

- Bostik Clic Protect

- Homax

- "Titanium"

- Application technology

- Deformation gap sealing

Why sealant is needed

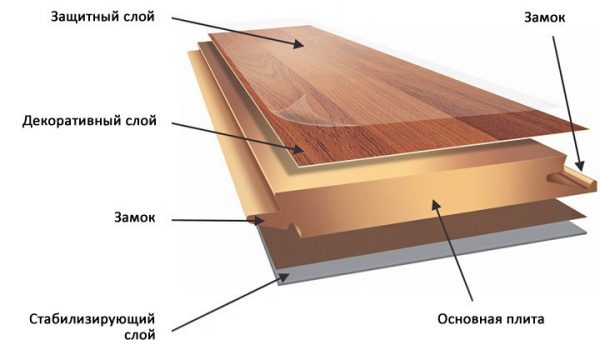

Laminate is a floor covering in the form of small planks (lamellas) made on the basis of wood-fiber boards. This material consists of the following layers:

- carrier;

- decorative;

- protective (acrylic or melamine).

The topmost layer - protective - is designed to prevent swelling, cracking, damage to the laminate due to moisture. During installation, the lamellas are interconnected by joining special locks: grooves and protrusions located at the edges of the elements. These locks, in addition to the reliable retention of the material on the floor, perform another practical function: they protect the coating from the ingress of water inside.

Despite the double moisture protection mechanism, with significant accumulation on the surface, it easily seeps into the locks, inside the lamella itself and even under it. The remaining layers of the laminate, except for the protective one, react sharply to such an “invasion”: they begin to warp, crack, and the fibers are strongly deformed. If the room is flooded, the laminate will have to be completely changed: it will instantly lose its attractiveness and swell. But processing the locks with sealant will help to close the cracks in the coating, protecting it from getting wet.

Laying laminate with sealant has huge advantages. The sealant itself is waterproof, therefore it reliably closes seams, joints, gives protection to the lock joints, which seriously prolongs the trouble-free operation of the laminate. In addition, the floor covering after sealing can withstand higher loads, even heavy furniture will stand on it. The lamellas will not move when moving objects on the floor.

Other advantages of using sealant:

- the possibility of wet cleaning, the use of detergents;

- suitability for any type of laminated and parquet board;

- easy dismantling (unlike laying on glue);

- lack of influence on the characteristics of the coating itself;

- quick drying;

- simplicity of work;

- harmlessness to humans;

- no stains on the floor.

It is also worth noting the increase in the level of sound insulation of the room after applying sealant: audibility is significantly reduced. It makes sense to use it where there is constantly high humidity, for example, in the kitchen. If the air in the room is dry and the room is regularly ventilated, you can not lock the locks, although even in such cases, the tool helps to protect the laminate from drying out, deformation and reduces the risk of damage from flooding by neighbors.

to contents ↑Sealant composition

After drying, the sealant is an elastic rubber sealant for laminate joints. Accordingly, in its composition there are components that provide strength, the ability to withstand vibration, dynamic loads. The basis of the sealant is silicone or acrylic that meets all the specified requirements.

The composition of the funds also includes various plasticizers, reducing the viscosity of organic extenders, mineral compounds. Other possible sealant components are:

- antiseptics and fungicides;

- quartz flour;

- a piece of chalk.

to contents ↑Colored sealants additionally contain coloring agents (pigments). They are designed for specific shades of laminate and are most often gray, dark brown, wood tones. There are also transparent, colorless products on sale, suitable for any type of material and almost invisible on it.

Properties and characteristics of the sealant for the laminate

Unlike glue, sealants do not stick lamellas together, they serve as a kind of rubber sealant. In addition to a highly elastic composition, the products differ in such properties:

- strength, durability;

- resistance to various external influences;

- ability to withstand humidity, temperature changes;

- concealment of cracks, joints between the slats.

Many sealants are applied directly from the tubes, but to work with some of them, you will need a special mounting gun. Due to the lack of strong stickiness, it is possible to wipe off the droplets of the sealant, as well as remove its excess without any special problems.

to contents ↑Types of compositions for processing laminate locks

Several varieties of sealants are available on the market: gels, silicone, acrylic compounds. Also, for the joints of the laminate, other means are applied that are not related to sealants: wax pencils, grouts, mastics, "liquid plug".

Laminate Sealant Gel

Such sealants are packaged in tubes of 125-150 g and look like a simple toothpaste. By consistency, they look like gel, look like jelly of a colorless or dull white hue. It is not difficult to work with them, so the tools are very popular in home repair.

Gels can be used at temperatures from -20 ... to +40 degrees, they are waterproof, elastic, do not respond to ultraviolet radiation. After applying them with a thin layer on the crests of the locks, the lamellas immediately join with the parts already laid. Excess gel is immediately removed with a napkin, and as it dries, a plastic spatula is used for this purpose. Gel sealants can be used even in unheated rooms, since the floor covering will not lose strength and appearance.

to contents ↑Silicone sealants

Such funds are the most sought after. They are based on silicone rubber, as well as adhesive primers, plasticizers, antifungal agents and vulcanizers - solidification accelerators. Silicone sealants are thicker than gel; they resemble a white translucent cream. Also on sale are colored products made in different shades.

Silicone has excellent elasticity, so the floor covering will not deteriorate even from strong vibration. Sealants are safe for health, have no smell, do not lead to the appearance of spots on the surface. After drying, the floor will be protected from moisture. If you need to replace one lamella, it can be easily separated from the surface, because silicone does not stick locks.

to contents ↑Acrylic Sealants

Among acrylic sealing compounds, colored ones are most often found. Their base is acrylic, and calcium carbonate, plasticizers, and titanium dioxide may also be present among additives.You can use such sealants not only for installing the laminate, but also for sealing chips, cracks, and other coating defects.

to contents ↑Acrylic makes the floor no less durable and impervious to water than silicone. Such sealants are distinguished by vapor permeability, resistance to UV radiation, and aesthetics of seams. After drying, the joints should be painted if necessary. Unfortunately, acrylic compounds can only be used in heated rooms, since they do not differ in frost resistance.

Most popular brands

On sale you can find sealants from different manufacturers. To choose the right product and purchase the best option, you need to pay attention to quality-determining factors:

- lack of an unpleasant smell and harmful substances in structure;

- ease of removal from the surface after drying;

- short polymerization periods (long-time non-curing sealant will seriously complicate the repair);

- convenient method of application;

- moderate cost (depending on the user's budget).

Below are described the most famous sealants that are well suited for the laminate and can be used in its installation.

to contents ↑Click guard

Click Guard sealant is made in Germany. It can be used for laminate of any class, price category, for all types of locks and protective coatings. Thanks to the elongated nozzle on the tube, it is not difficult to apply sealant; you will not need to purchase additional tools. The product dries in 15 minutes, its excess can be easily removed from the floor covering. 7-10 square meters of floor consumes one package of sealant.

to contents ↑Click protect

This product is made in Sweden. The composition is moisture resistant, colorless, is widely used when laying any types of laminate, parquet. Due to its economical consumption (15 square tube) and fast polymerization (half an hour), the sealant is highly respected by professionals.

Soudal

This color acrylic sealant is suitable for installing laminate flooring, sealing cracks, chips, cracks, scratches on this material, as well as for restoration of old coatings. It is completely safe, odorless, available in different color variations. Other advantages are the possibility of applying for laying "floating" coatings, a high level of adhesion, ease of removal of excess. To work, you will have to purchase a special gun, without which application is difficult.

to contents ↑Roci aquastop

This wax sealant with the addition of acrylic is designed for laying lamellas whose side surfaces do not have a protective film. It creates a reliable, durable connection of locks, eliminates creaking of the floor covering, and prevents the penetration of moisture. You can apply sealant with a regular brush.

to contents ↑Masterfix

Sealant "Masterfix" is made in Russia. It has a low price with high quality, is universal, suitable for all types of laminate, has powerful water-repellent properties.

Quick step

Quick Step Sealant from Belgium is specially designed to further protect the laminate from moisture. It allows you to mount this flooring even in the bathroom. Sealant differs in elasticity, full transparency, quickly hardens. The gel is consumed sparingly: the tube is enough for 10 square meters.

Bostik Clic Protect

Bostic is a French laminate sealant sold in 125 ml tubes. It provides long-term protection against penetration of moisture into the joints between the planks, is suitable for laying parquet by the floating method, colorless, does not leave spots.

Homax

Homax sealant was created in Germany using the latest technology. It is available in different colors (for example, “light oak”), has an environmentally friendly composition, is completely safe for people. Sealant has a high degree of adhesion to wood, laminate, moisture resistant, provides a reliable connection of elements.

to contents ↑"Titanium"

The tool "Titan" is a colorless gel for the joints of the laminate. It allows you to make seams durable and moisture resistant, dries in 15-20 minutes, is economically consumed. Among the shortcomings can be called an unpleasant odor, which completely disappears after polymerization.

Application technology

Typically, the treatment of joints with a sealant is carried out when laying a new laminate. It is also recommended to make sealing during the restoration of an old coating with parallel patching of chips, cracks, and other defects. Sealant is applied without gaps, in continuous. Tips for doing the job:

- it is necessary to form a joint correctly so that the seam between the individual elements does not restrict freedom of movement;

- the sealant should not fall on the bottom or top of the lamellas - it is applied only to the sides, otherwise the risk of seam rupture under load increases;

- when filling wide joints, it is advisable to use cellophane overlays on the front side, which will protect the elements from the ingress of sealant.

To apply the product, take a tube with a sharp tip or a cylinder inserted into the gun. The tip of the package is placed in the groove of the lamella at an angle of 45 degrees, squeezing out the composition with an even strip. When working with an assembly gun, it is much easier to achieve uniformity of the layer than when using tubes.

Excess sealant is removed with a narrow spatula previously moistened with water. After connecting the strips, the sealant protrudes to a surface in a small volume: it also needs to be removed, but only after 15-30 minutes, when the polymerization occurs. It is better to use a plastic spatula for this, metal can leave scratches.

to contents ↑If restoration of an old covering is carried out, it is necessary to remove in advance the previous layer of sealant (if any). This can be done mechanically: picking up with a spatula and stripping off a strip. Sealant residues must be washed with solvent. Before smearing the laminate with a new tool, the elements must be wiped with a soft rag.

Deformation gap sealing

The sealant will help to reliably close the expansion joints that are obtained after laying the coating along the walls. Without this, moisture can seep inside, and all efforts to seal the sides of the lamellas will be futile. The work is carried out in the following stages:

- wipe the laminate with a damp cloth from the side that will be near the wall;

- glue the deformation gap with construction tape so that the product does not fall on the front side of the laminate;

- fill the joint with sealant, smooth it with a rubber spatula immediately after application;

- remove the adhesive tape, gently wipe the finished seam with a damp cloth.

During installation, do not fasten the lamellas too tightly, otherwise they may warp during operation. The locks must snap into place so that subsequently they do not have free play. Despite the slow speed when using sealant, the quality of the flooring will be an order of magnitude higher, the laminate will last longer and without complaints.