Sealants based on bitumen and rubber compounds are widely used in construction and various industries. They were developed back in the 60s of the last century, later their composition was improved, as well as the form of release, application methods.

- Features and characteristics of sealant

- Application area

- Advantages and disadvantages

- Varieties of sealants

- Sealant "Vicar"

- Sealant Orgavyl

- Sealant "TechnoNikol 45"

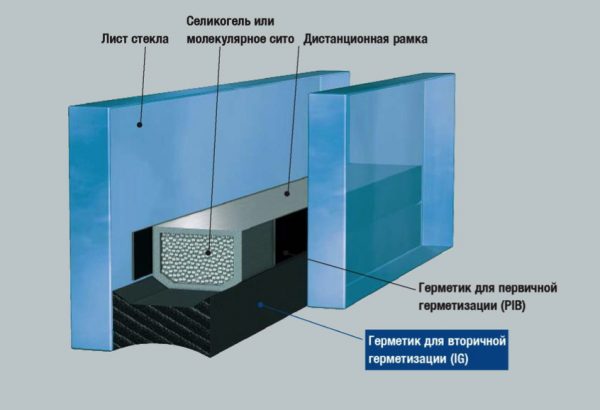

Butyl sealant is used to produce double-glazed windows, it can also act as a means for sealing headlights and for many other purposes.

Features and characteristics of sealant

Butyl sealant is understood to mean a one-component thermoplastic mass based on synthetic rubber (polyisobutylene), therefore, the material is no less often referred to as “butyl rubber sealant”. Among other things, compositions of this kind contain hydrocarbons, oxygen and sulfur compounds, substances based on nitrogen, various metals.

Rubber as a part of sealants possesses durability, high adhesive properties to aluminum, glass, sheet steel (adhesion indicators - not less than 90-93%). Due to its special qualities, it can easily penetrate into joints, joints, cracks, reliably clog them and protect them from moisture, dust, and dirt.

In appearance, the sealants are a plastic gelatinous mass, quite thick in consistency. They can be white, gray or black, and light shades can be tinted with any facade paint or dry pigments before use. Funds are sold in tubes, buckets, banks, barrels, have certificates of conformity indicating the composition and technical characteristics. Sealants are applied using extruders - special machines, where they are heated to + 110-150 degrees, softened and fed under pressure. Some modern formulations can be applied cold.

to contents ↑Application area

Butyl sealant turned out to be the most demanded in the field of manufacturing double-glazed windows. It is sealants that seal gaps, joints, connect individual elements. Also, the tools have found their application in gluing thermal insulation panels, sealing air conditioning systems and countertops. They are suitable for sealing containers, vessels, and other non-food containers.

More sealants can be used for:

- preventing gas escape from various chambers;

- compounds of destroyed glass, metal, wood;

- headlight repair by professionals and amateurs;

- various repairs and construction purposes;

- sealing joints of water pipes;

- thermal insulation of terraces and greenhouses;

- sealing joints of reinforced concrete, balcony slabs;

- anticorrosive protection of steel buildings.

Advantages and disadvantages

Before purchasing, it is recommended that you carefully study the advantages and disadvantages of this sealant. Its advantages are:

- lack of toxic volatile components;

- optimal heat conductivity and breathability;

- excellent adhesion with metals, alloys and other popular materials;

- high elasticity;

- temperature tolerance from -55 to +100 degrees during operation;

- long service life;

- safety for people, animals, environment.

Such sealants dry quickly, they can be applied to a wet surface, which is why the adhesion quality will not change. The products have an affordable price, especially when spilling large containers into containers.

Sealants also have flaws. They are not available in color versions, although the addition of pigments or paints can solve this problem. With frequent temperature changes, the seam is able to lose strength and extensibility. Due to the loss of elasticity, it begins to crumble, crack, break.

to contents ↑Compared to other types of sealants, butyls have a less wide range of applications. Also, the means do not tolerate the effect of ultraviolet radiation: with frequent contact with the surface of the seam, the sun's rays destroy them, which can lead to depressurization of parts. However, many modern formulations do not have such a drawback.

Varieties of sealants

Most butyl sealants require special conditions for application: they must be heated before polymerization. But thanks to modern additives, some materials require only a cold application method, their deformation-strength characteristics are achieved even without heating. Typically, the compounds that are applied by the cold method are used only for external work, whereas after heating, sealants may well be used on internal ones. Examples of high-quality products are butyl sealant TechnoNicol 45, Titanium, Vikar, Orgavil and others.

to contents ↑Sealant "Vicar"

This butyl rubber sealant has many advantages, which is why it is widely used in production and repair. The composition includes bitumen and rubber, as well as fillers, solvents, and targeted technical additives. Using sealant, you can work on concrete, tile, ceramics, natural stone, PVC, metal, it adheres to silicone, other types of sealing agents.

The product is characterized by moisture resistance, long service life, elasticity, and due to the improved composition - good tolerance of ultraviolet radiation. The sealant does not respond to other atmospheric factors, has high strength characteristics. "Vicar" is used for such purposes:

- strengthening of joint seams, joints inside and outside the premises;

- increase heat resistance of buildings;

- closing gaps between sandwich panels;

- sealing roofs, chimneys, ventilation systems;

- repair of seams on the car body, corrosion prevention.

The product can be found on sale in various forms: in the form of a paste packaged in 310 ml tubes (gray, black), in ribbons of the same colors. The tape is easy to use, therefore it is highly appreciated by professionals. It is a double-sided adhesive film that is not afraid of moisture, is applied to the surface without heating. Usually, with the help of a tape, they repair stained-glass windows, roofs, ventilation pipes, connect the vapor barrier elements, apply it during the installation of water supply and sewage systems.

to contents ↑Sealant Orgavyl

This black tape sealant is manufactured in the United States by Orgavyl. Most often it is used for sealing holes on car windows, for sealing auto optics during installation. The tool is of high quality and has a lot of advantages:

- does not crack, does not shrink;

- provides reliable sealing, protecting joints from dirt and water;

- has a high degree of moisture resistance, oil resistance, is not destroyed by the action of chemicals;

- no toxins, odorless;

- dries quickly;

- leaves no spots.

to contents ↑This sealant is easy to remove even after application: you just need to warm the seam well and then remove. It is possible to use the removed material repeatedly, it does not lose its properties. It is enough just to heat with a building hairdryer and apply a plastic mass to the treated surfaces. The only disadvantage of the sealant is its high cost, although its consumption for sealing auto optics is quite small.

Sealant "TechnoNikol 45"

The product under this brand is positioned as a sealant for professional use. It has many advantages - it dries in just an hour, resistant to temperature extremes and any atmospheric factors. Sealant is indispensable for strengthening joints and waterproofing building structures made of any material. The composition is also used for corrosion protection of steel buildings, to prevent the destruction of ceramic products, glass, modular wooden options.

The sealant is characterized by a low consumption of 1 m. For example, for 1 m of a seam 1 cm wide and 5 mm deep, only 45 g of the composition will leave. "TechnoNikol 45" is sold in buckets of 8-16 kg, it is easy to find it in any hardware store. Operation of products after drying of the joints is possible at temperatures of -50 ... + 80 degrees. Work with butyl compounds in compliance with safety measures, avoiding contact with the skin, into the body, using protective clothing and gloves.