There is a cutting board in any kitchen, and the most presentable and reliable look are wood products. Such boards are made from solid pieces of wood, cross cuts, small glued blocks or plywood: the latter option is the most inexpensive, but has a shorter service life.

- What is the treatment for?

- Varieties of tools and selection rules

- Vegetable oils

- Mineral oils

- Popular mineral oils

- Beeswax

- Other means

- How to evaluate the quality of mineral oil

- How to make a mixture at home

- How to properly impregnate

Regardless of the manufacturing technology, the question remains urgent: how to process a cutting board from wood so that it does not become worthless? Only special impregnations will help prevent cracking of the utensils and the settlement of fungus and mold in the wood.

What is the treatment for?

With daily cooking, the cutting board is subjected to severe stress. It is regularly scratched with a knife, a kitchen hammer, moisture penetrates into the pores of the material, juices of vegetables and fruits, from them the dish detergent may not be completely washed out. The average period of operation of wooden utensils is about a year, after which it loses its functionality and attractiveness.

Special processing of the cutting board with oil compositions allows you to fill the pores of the wood and prevent wetting, swelling, deformation of the product. Impregnation also has the following objectives:

- prevention of absorption of unpleasant odors with wood;

- prevention of cracks, chips, other defects;

- preventing the colonization of material by harmful microorganisms;

- prevent rot and microbial toxins from entering food.

With the periodic use of impregnation, the term of the possible operation of the cutting board increases, which will seriously save money, because such products are expensive. Initial processing should be done immediately after the purchase of the utensil, while it has not yet been involved in cooking.

It is important not to wash the product before impregnation, because oils can “lock up” the remaining moisture inside the wood fibers. To really extend the life of the board, you need to process it regularly.

to contents ↑

Varieties of tools and selection rules

You can cover the cutting board with synthetic and natural oil, the main thing is that it does not contain toxic components and is absolutely harmless to humans. The oil must be resistant to high temperatures (hot water), do not spoil under the influence of room temperatures and do not rancid: otherwise the cutting board will smell unpleasant.

Impregnation tips are as follows:

- do not lubricate pine boards with linseed oil products due to poor material compatibility;

- well suited for processing oil utensils that are produced by the same manufacturer and are sold as a set;

- mineral compounds are often sold in building materials stores, and far from all of them are suitable for food purposes;

- the strongest oak planks are best lubricated with a mixture of mineral oil and wax;

- thin plywood boards also require oil treatment; for this purpose, natural impregnations are well suited.

Vegetable oils

Traditionally, natural oils are used for processing wooden products - sunflower, olive, nut, linseed, sesame and others. Their main advantage is environmental friendliness and complete safety for health. But any vegetable oil for processing boards has a significant minus - without the addition of preservatives, it spoils, gains a rancid taste, smell.

The reason is the increased production of butyric acid bacteria - the inhabitants of the product - butyric acid, which gives such a taste. Some funds deteriorate after a couple of months, while others need about 9-12 months to get a painful “aroma”.

Vegetable oils dry for a long time. Two or three days is better not to pick up the board - it will greatly dirty everything, leave oil stains. As a result, it will take more than a week to apply several layers of impregnation. Some people choose drying oil for work, because it is also cooked on the basis of oils, but its drying time is not much shorter, and wear is quick.

to contents ↑Mineral oils

The best board oil is mineral. Any synthetic products are made on the basis of petroleum products, while special impregnations for kitchen boards are thoroughly cleaned, becoming safe. Here are their merits:

- lack of smell, taste;

- availability in any convenience store, in pharmacies;

- the ability to apply in a thick layer (everything is absorbed);

- optimal protection;

- long service life;

- simplicity of work;

- lack of color;

- improving the appearance of the product.

Popular mineral oils

Similar tools are produced by many manufacturers. In order not to make a mistake and get a really high-quality composition, you can pay attention to the following brands:

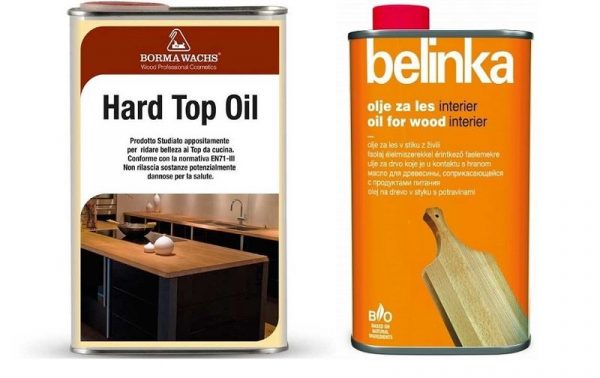

- Hard Top Oil-265. Mineral oil from Italy with a long service life, high wear resistance, completely safe for humans. Suitable not only for kitchen boards, but also for the handles of knives, butts of weapons.

- RuChet-100. Inexpensive Russian oil based on petroleum products and petroleum jelly. It is used to protect wooden boards from moisture, bacteria, fungi, dryness and cracking. Also suitable for greasing knives, impregnating plywood products.

- Belinka-135. The oil has a high penetration depth, gives wood objects a pleasant shine. Serves for a long time, does not require frequent application.

Beeswax

Natural wax is considered a natural sealant with antiseptic, antifungal properties. It can be used independently or added to oils, as it increases the moisture resistance of wooden products, clogging too large pores.

Wax literally closes cracks, chips, small cracks, seriously increasing the life of cutting boards. It is distinguished by the ability to create a stronger protective film than oil can do, and it also gives things a pleasant smell.

to contents ↑Other means

To prevent damage to wooden boards, coconut oil, which is rare for medium latitudes, can be used. It contains a large amount of fat, while retaining its properties for a long time and does not become rancid even at room temperature. Cocoa butter is about the same quality, however, the price of these products is quite high. You can also use petroleum jelly for processing kitchen boards: it is cheap and is sold at any pharmacy.

to contents ↑How to evaluate the quality of mineral oil

To buy a really worthwhile oil, you need to carefully read the instructions and clarify the following characteristics:

- Water resistance. A good remedy not only penetrates into the pores, but also repels water, even with direct contact with it. If the moisture resistance is insufficient, the rotting of the wood will continue, the product will collapse.

- Environmental friendliness. The composition should not only not contain harmful components, but also must not emit them when heated, be chemically inert, and do not lead to the formation of hazardous compounds with household chemical components.

- Sufficient penetration. Some waxes, glazes have only a superficial effect, and the oil must penetrate precisely into the structure of the tree.

- Colorlessness.A good oil does not change color, the pattern of wood, although if necessary, pigments can be added to it to tint the product.

- Lack of smell. A quality product does not have extraneous odors, although some formulations contain certain perfumes.

How to make a mixture at home

If you could not buy the necessary impregnation for boards in the store, it can be done at home, with your own hands. The simplest recipe is this:

- buy petroleum jelly in a pharmacy;

- purchase beeswax in a specialized store;

- combine 4 parts of oil and 1 part of wax cut into pieces;

- melt the mass in a water bath, stirring to give uniformity;

- cool the product to room temperature;

- use for wood processing, keep in the refrigerator.

It is undesirable to replace beeswax with paraffin, stearin - the latter strongly clog the pores of the wood, which seriously violates its vapor permeability and can provoke rot.

to contents ↑

How to properly impregnate

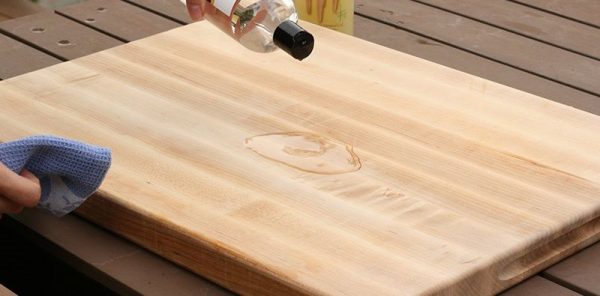

If the board is new, it is immediately treated with oil in 2-3 layers, and each subsequent one is applied only after absorption of the previous one. The utensils are dried in a well-ventilated area. The old board is pre-prepared: carefully sanded with the finest emery cloth to remove all large roughnesses. The product is thoroughly dried - even a small amount of moisture should not remain inside the wood.

After drying, the boards are abundantly applied with a brush, cotton or gauze swab over the entire surface and from the ends, after 20 minutes the excess is washed off. Movements are carried out only along the fibers of the material. Apply impregnation in 2-3 layers 10-12 hours after each previous one.

Plywood boards also need special care. Unlike solid ones, they are made from thin sheets of wood glued together, therefore they are more sensitive to moisture. With the wrong approach, plywood boards swell quickly, mold settles between failures.

Such products are treated with mineral oils with the addition of beeswax, applying the product with a roller, a soft brush, after laying the board in a horizontal position. Such work is done at least once a month.

In order for the wooden cutting board to last longer, the following tips are followed during operation:

- after each use, wash the utensils with a minimum amount of detergents, wipe the remaining moisture with a towel, then dry thoroughly;

- do not allow a long stay of the board in the water;

- depending on the intensity of use, the board is treated with oil every 2-5 months;

- heavily damaged by knives, the product is first ground, polished, giving it smoothness, and only then subjected to oil soaking.

If you do not ignore the rules for caring for wooden boards, regularly treat them with high-quality oil and always dry them, you will not have to spend money on expensive utensils. The board will remain safe for health, functional and beautiful, transforming the interior of the kitchen!