Linoleum as a material for flooring has long been a leader. Its advantages are obvious - ease of installation, low cost, beautiful appearance. The disadvantages include the need to dock individual pieces if they are not suitable for the size of the room.

- Welding Features

- Cold welding process

- Types of welding for linoleum

- Type A

- Type C

- Type T

- Compositions for welding

- Tytan

- Axton

- Tarkett

- Instructions for use

- Seam formation

- Cleaning the base and seam

- Cold welding

- Removing excess glue

Connecting parts of the coating is better with special types of glue. Cold welding for linoleum is an ideal adhesive that can be used even at home.

to contents ↑Welding Features

In the presence of seams, joints, the integrity of the flooring is violated. This not only spoils the aesthetics, but also reduces functionality. The edge of the canvas will constantly bend, you will have to cling to it with your feet, and when washing the floor, water will fall under the formation. The result is a decrease in linoleum life.

How to solve this problem? The best way is gluing the joining point with cold welding. There is also hot welding, but it requires special knowledge, equipment, materials (cord, building hair dryer). The cold method is the best choice, it is available to everyone. A special glue is used to connect the edges of the PVC material. The advantages of the technique are obvious:

- solidity of seams, while they are almost invisible visually;

- lack of need for special equipment, expensive tools;

- simplicity of work - skills for its implementation are not required;

- low price - the glue is inexpensive, so the repair will be budgetary, the expense is low;

- short installation time - it will take a short time to carry out welding work, it will take a minimum of time;

- universality - this method can be used to glue small and large, complex joints.

The disadvantages of cold welding are few. It is impossible to glue with the help of such means a very thick, multi-layer linoleum. The joint will not be strong, it will remain noticeable. It is also not recommended to weld seams with glue if a floor covering on a felt basis is used. This material is thick and may not melt well from the components of the product. However, there are special adhesives for this type of linoleum.

to contents ↑Cold welding process

Sticking the flooring by welding is no more difficult than using conventional repair compounds. In fact, inside the tubes, vials for cold welding, there is a solvent that is able to melt and weld polyvinyl chloride.

Here is how a thick adhesive mass acts after application to linoleum:

- chemical components penetrate the surface of the material, partially corrode it;

- the base in the treatment area becomes liquid;

- the two edges of linoleum are joined together, the seam is strong and almost invisible;

- after a few hours, the seam hardens completely, the coating is ready for use.

A new joint does not stand out against the background of the canvas, because it does not respond to temperature fluctuations. Since the components of the adhesive are “related” to PVC, the strength characteristics of the seam are not inferior to those of linoleum itself. Only an unpleasant smell, toxicity of glues can scare away the master. But with the proper organization of work and compliance with security measures, everything will pass without problems.The master should have gloves, a respirator, and good ventilation should be provided in the room. This will help to avoid inhalation of solvent vapors.

to contents ↑Types of welding for linoleum

You can glue the PVC flooring using three types of means, the difference between them is in the composition and properties. Glues are used for different purposes, it is advisable to follow the recommendations of the manufacturers.

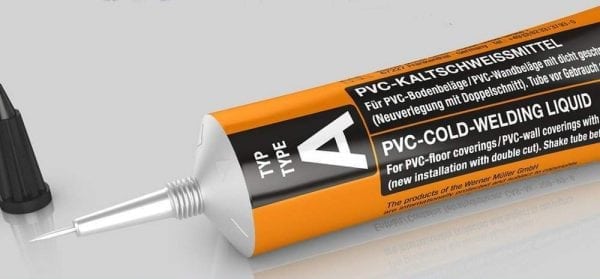

Type A

Such products due to the large volume of solvent are liquid in consistency, therefore, they can only connect joints with a narrow gap (up to a millimeter). If the distance between the pieces of linoleum is large, type A is not suitable. It is convenient to apply glue, the bottle is equipped with a thin nose. Advantages of funds:

- high strength of the seam;

- imperceptibility of the joint for the eye;

- speed of ongoing reactions.

to contents ↑It is best to use Type A materials for gluing small pieces of linoleum, small joints. Ideally used on factory edges. If it turns out to cut the coating with a significant error, such tools can ruin it.

Type C

Type C materials act as adhesives for old flooring. They are very thick, the bottles do not have a thin nose, are equipped with a wide neck. It contains little solvent and a lot of liquid PVC. Such adhesives are used to fill the joints, and can even cover wide cracks (several millimeters). Most often, type C adhesives glue linoleum during the repair of an old coating. Rough edges are not an obstacle to their use.

to contents ↑Type T

This type of glue provides a very high quality seam, but is mainly used to glue felt and polyester coatings. Due to the stronger melting, the composition is suitable for bonding thick, multilayer canvases. Due to technical difficulties, type T is more often used by professional repairmen.

to contents ↑Compositions for welding

Glues are produced by different manufacturers, but their properties are almost the same. The composition necessarily includes a solvent and a filler. As the last is liquid PVC. As a solvent, tetrahydrofuran is most often used by manufacturers, less often polyurethane. Changing the percentage of solvent and filler allows you to get different types of glue.

Consumption of cold welding compounds depends on the qualification of the performer, linoleum thickness, density of the product. The most popular adhesive brands are described below.

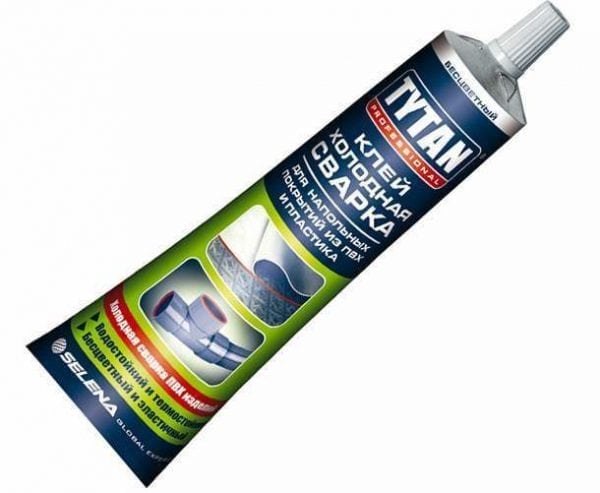

to contents ↑Tytan

"Titanium for cold welding" - these are several types of adhesives under one brand. The most famous Tytan "White" 100 ml is a one-pack product with a volume of 100 ml. It is supplied in the form of a rod, inside of which is a base and a solvent. Before use, just shake the bottle. The glue withstands very large loads, sets in 5 minutes, the bottle lasts for 45 m of joints. It can be operated as cold welding for metal.

Also on sale you can find glue "Titan" type C, which is allowed to weld gaps up to 4-5 mm wide. It is implemented in a two-pack form, before applying the components must be mixed. In addition to high strength, temperature resistance should be indicated - the adhesive joint can withstand up to +150 degrees.

to contents ↑Axton

Axton glue - Polish tool for cold welding, is available in tubes of 60 g each. The composition has excellent reviews among users, it helps to weld joints without the subsequent appearance of waves, bubbles. The material dries quickly, can be used on joints up to 3 mm. Among the minuses, the masters note:

- the absence of a thin needle, the inability to put on a tight joint due to a thick nose;

- high consumption - the tube is enough for a 4-5 m seam;

- shrinkage of the product after drying, so it is applied in large volume.

Tarkett

The German company Tarkett specializes in PVC flooring. The manufacturer knows a lot about glues and produces very high-quality and reliable products. The tube has a steel needle that does not clog or break, its shape is very convenient for work. The strength and tightness of the joints will be at the highest level, while the seam is completely invisible. The glue is suitable for all types of linoleum, even multi-layer, while it is also suitable for uneven trimming.

to contents ↑Instructions for use

How to glue the linoleum joint with cold welding? To carry out all the work correctly, you must strictly follow the instructions. It is described step by step below.

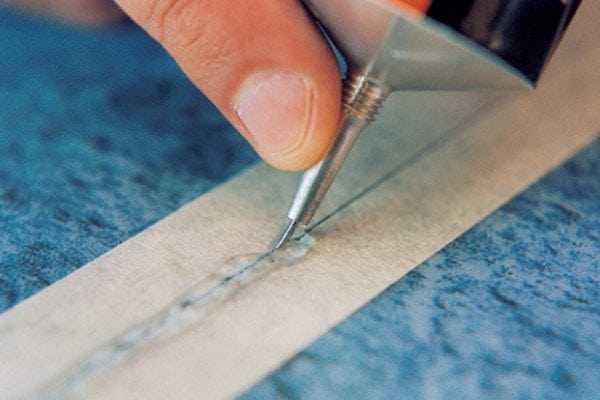

Seam formation

After acquiring the coating, its approximate fit, you need to form the optimal seam. To do this, lay both pieces as they will lie on the floor. In this case, the overlap should be 5 cm. Next, you need a strong metal ruler and pencil. Fasten both edges of the coating to each other with double-sided tape so that they do not move during cutting. Then marking is done strictly in the middle, firmly pressing the coating with a ruler. After that, they cut according to the marking with a sharp knife to get smooth edges.

to contents ↑Cleaning the base and seam

Before gluing, you need to thoroughly clean the floor of dirt, remove the rest of the old coating, vacuum. Before work, all parts must be dried. Also, as a preparation, the edges of linoleum should be protected from damage. Cold welding contains aggressive components that can corrode material. Glossy linoleum is particularly affected. To avoid such troubles, you need to buy a wide masking tape and paste over the edges of both canvases, leaving a few millimeters for glue.

to contents ↑Cold welding

Before work, you need to prepare a clean cloth or cotton swabs to remove excess and smudges of glue. There are two ways to apply the product:

- First. Using the nozzle of the tube, squeeze the glue to both edges at once. At the junction, linoleum will become liquid, the edges will melt.

- Second. Lubricate only one edge, attach it to the floor. Then glue the second edge with glue and lay tightly next to the first. Flatten, smooth the seam.

After a few hours, you can walk on the floor without fear, the exact drying time is indicated in the instructions for the glue. When the linoleum dries, you need to remove the masking tape.

to contents ↑

Removing excess glue

Often, excess composition flows out. Do not touch them while welding the edges; this can cause detachment of the floor covering and destruction of the seam. Dried cold welding is removed in 2 steps. Since the fresh seam is flexible, a crater may remain if it is pulled hard and cut. It is better to first cut off the excess bulging on the surface, and after a day to finish the job. You can do all the work yourself, without the help of masters. Installation of a weld is a painstaking task, but quite real!