To create an even and high-quality coating when painting with water-based or powder paint, experts recommend using a spray gun. But since many high-performance models cost a lot of money, it is advisable to make a real atomizer from improvised materials.

- Aerosol spray can

- Vacuum cleaner spray gun

- Refrigerator for making a spray gun

- Spray gun holder

- Ballpoint Sprayer

- Production of a spray gun for powder paint

- conclusions

Such an apparatus can be made from a vacuum cleaner, a refrigerator compressor, an automobile camera, and even from a conventional ballpoint pen, while it will not be inferior to factory analogues, and even surpass them at some points, this applies, first of all, to the price of atomizers.

Homemade spray gun is perfect for water-based paint, for whitewashing lime and other decorative coatings. For painting with powder paint, professional machines with high power are needed, but such designs can also be made at home. Therefore, for many, the question remains how to make a spray gun with your own hands and get a high-quality result.

to contents ↑Aerosol spray can

A hand spray gun from an aerosol spray can is one of the simplest types of home-made paint sprayer for water-based paint, which is very easy to make from improvised materials. For work, the following items must be prepared: a plastic bottle, a bicycle chamber, an aerosol can, for example, from a deodorant used, and a bicycle pump.

The work is carried out in the following order:

- cut a nipple with a cover with a diameter of 3 cm from the bicycle chamber;

- make a hole in the bottle;

- glue a nipple to the inner wall of the bottle, which will perform the function of forcing the air mass;

- use a hacksaw to cut a spray module with a valve from the can (the can must be selected so that its size matches the diameter of the cork from the plastic bottle);

- attach the valve to the plug by cold welding, it is important to create an absolutely tight connection, since the structure will function under pressure;

- to test the device under pressure not exceeding 3 atmospheres.

The spray can made at home from the spray can works on the principle of an airless spray and perfectly paints the surface both when painting with a water-based composition and when whitewashing with lime.

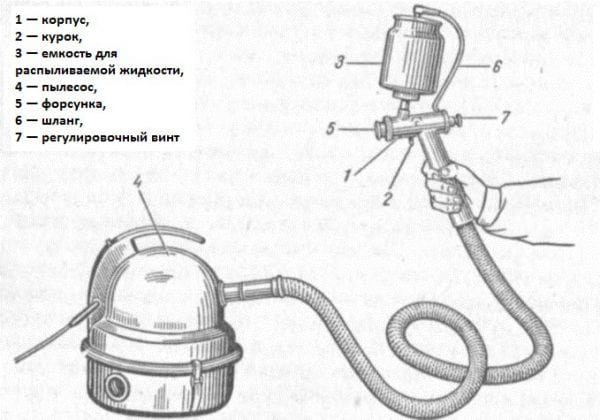

to contents ↑Vacuum cleaner spray gun

If you plan to paint walls or ceilings in a large room, then working with a hand-made home-made sprayer will be quite problematic. In this case, you can try and make an apparatus with automated air supply. To do this, you need a compressor from the refrigerator or an old vacuum cleaner. Units made from a compressor of a refrigerator or a vacuum cleaner do an excellent job with the water-based composition, but are not suitable for powder paint.

Old Soviet vacuum cleaners have an advantage over modern technology in that their design involved connecting the hose not only to the inlet pipe, but also to the outlet, and they could function both by “blowing” and “blowing”. Models presented on the modern market do not have such opportunities.

If the use of the vacuum cleaner is no longer planned, then in it you can change the direction of traction, in some cases it will be enough to change the poles of the terminals that are connected to the stator and rotor. After this, it is necessary to carry out several operations that will allow you to fully use the old unit as an electric spray for painting:

- Choose a bottle made of plastic or glass with a wide neck (with a diameter of at least 5 cm and a volume of up to 2 liters).

- Cut a cork from the foam that fits the neck of the bottle in size. The cork should have a rectangular ledge, which allows you to insert into the hole at right angles to the tube from a ballpoint pen or dropper.

- Make holes and insert tubes, one of which will supply ink, and the second will supply compressed air.

- Make another auxiliary hole in the cork, through which air will pass into the bottle, and when the volume of paint decreases, a vacuum will occur in a tightly closed vessel.

- Cut another foam plug, which will combine a spray gun and a vacuum cleaner hose into a single system.

Refrigerator for making a spray gun

An electric spray gun made from a compressor from the refrigerator works much quieter than a vacuum cleaner and provides significant savings when painting with water-based paint and whitewashing lime. But to make such a device is much more difficult.

- As a receiver, take an old fire extinguisher, bottle, canister or other tightly closed container.

- Remove the compressor and start relay; for this, the copper tubes have a bite or sawed off with a hacksaw.

- Turn on the power to determine which tube delivers air under pressure.

- Using a sealant or hose, attach a car gas filter to the pipe that draws in air, which protects the structure from dust.

- Connect the air pipe to the receiver with two gas hoses. For this, fittings fixed with a sealant are used.

- Install a diesel filter on the receiver’s outlet, which can be purchased at the auto parts store. The filter eliminates excess moisture in the incoming air and improves the quality of the spray gun.

- Mount the compressor and receiver on a solid base, such as a board. After that, you can turn on the spray gun and start the painting process.

Advice! The compressor must be installed in the same position as it was in the refrigerator, otherwise the device will not start. In addition, in the spray gun from the compressor, it is periodically necessary to change the oil. For this, the third tube is designed, which is inserted into the housing.

The spray gun made can equally well be used both for painting with water-based paint and for whitewashing with lime.

to contents ↑Spray gun holder

A simple holder for a spray gun with your own hands can be made from a regular plywood sheet about a centimeter thick. To do this, you must:

- cut a square of 25 x 25 cm from a plywood sheet, in which a circular hole is cut with a jigsaw, the size of which corresponds to the spray tank;

- insert the handle of the gun into the groove cut from the edge of the plywood board to the hole;

- install the stand on the legs of wooden blocks, the height of which should be chosen so that there is space below for accommodating the hose;

- a holder for the filter funnel can be additionally made to such a stand; for this, an aluminum wire is used, which is screwed to plywood.

to contents ↑

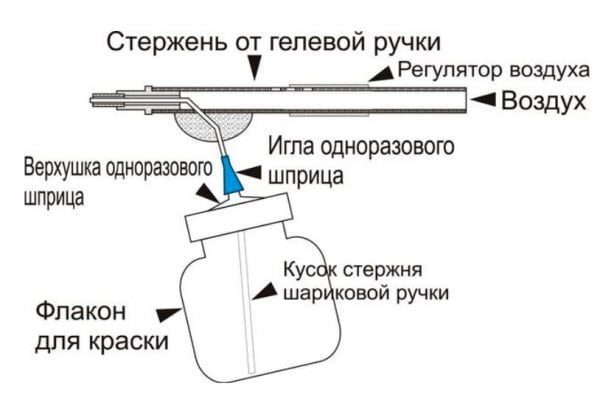

Ballpoint Sprayer

A homemade spray gun based on a compressor of a refrigerator or a vacuum cleaner is a rather complex system that needs certain knowledge, but everyone can make a simple mini-spray from a ballpoint pen. This hand-held device is used with a small cylinder of up to 1 liter, ideal for small finishing work involving water-based paint.

To make such a sprayer it is necessary:

- disassemble the handle and remove the paste from it, so that in the end you get an empty tube through which air will pass freely;

- cut off the tip of the bottom of the handle to get an expanded hole;

- disassemble the core, remove the remaining paste from it with alcohol;

- in the center of the plug make a through hole of the same size as the rod;

- perpendicular to the hole for the rod plug, a hole is drilled for the handle body;

- insert the core and body into the bottle, after which you can begin to stain. You will have to breathe the air in such a device yourself, so this method is not suitable for complex painting with powder paint.

Production of a spray gun for powder paint

Making a spray gun for powder paint is not an easy task, which requires professional skills and knowledge in the field of electricity. A common manufacturing technology of a spray gun includes the following tasks:

- Assemble the electrical module. For this, the core is formed from a piece of plastic water pipe and a wire wound around it with a ferrite element. This module is placed in a plastic vessel and filled with paraffin.

- Pick up the gun. An electric core is mounted in a plastic tee, while it must fit very tightly into it. The walls inside must be treated with glue to ensure the stability of the mechanism. All electric wires are brought out through the lower holes, which are sealed with paraffin, and the exposed core is covered with a casing.

- Connect the structure to the paint tank. A hole is drilled on the tee, where the tank is inserted, while the supply of paint is regulated by a rubber trigger.

- Remove the withdrawn wires and close them on the power supply, after which you can begin to conduct tests and fill the device with powder paint.

to contents ↑

conclusions

Thus, the manufacture of a spray gun with your own hands is a doable task. For more complex painting processes and frequent operation, it is advisable to make a powerful electric spray gun from a compressor - such a unit is not inferior in its performance to finished models. And for small one-time works on painting with water-based paint, a simple spray gun from a pen or spray can is quite suitable.