Construction and painting tools are gradually being improved. The usual brush and roller displaces the spray gun, which makes it possible to uniformly paint large areas in a short time. The device is convenient to use, but, like any equipment, sometimes it fails, ceases to fulfill its functions. What to do if the spray gun does not spray paint properly? Why, instead of a uniform ejection of paint, “spitting” fly out of the nozzle or is air just blowing?

- Varieties of spray guns

- Manual (mechanical)

- Airless

- What will be needed for repair

- Malfunctions and how to fix them yourself

- Hand tool

- Electrical appliance

- Tips for extending the life of the spray gun

Varieties of spray guns

To deal with these issues, you need to decide on the types of devices. There are two types of spray guns.

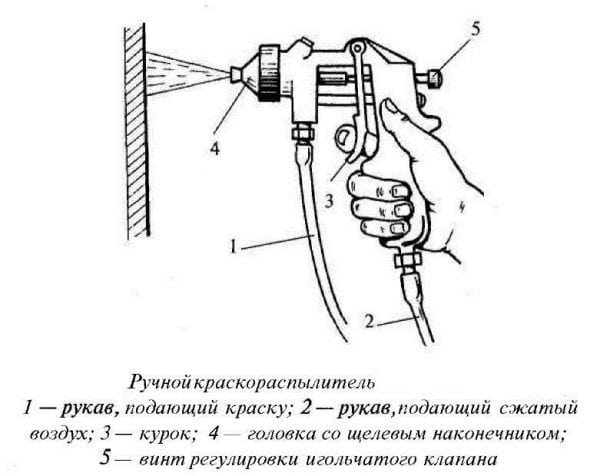

Manual (mechanical)

It runs on compressed air. Air is injected into the spray gun manually using a piston pump.

They can be produced:

- with the upper location of the tank, when the dye enters the nozzle under the action of gravity and its supply is regulated by changing the air pressure;

- with the lower tank, when the tank is attached from below, the solution is pumped into the nozzle using compressed air.

Airless

Also called electric. Sprays the coloring matter with the built-in pump.

Both of these varieties are very different from each other, and with seemingly identical malfunctions, the repair of a manual spray gun will be very different from the repair of an electric spray gun.

to contents ↑What will be needed for repair

Regardless of the principle of operation of the coloring mechanism, before proceeding with the diagnosis and troubleshooting, it is necessary to prepare the following tools and spare parts:

- a set of wrenches of various sizes;

- pliers;

- a screwdriver;

- repair kit and other sets of spare parts.

A spare parts store for repair and construction equipment will be able to offer several options for repair kits for troubleshooting spray guns. It could be:

- A standard repair kit consisting of several bolts and rubber seals (it is better to stock up on such repair kits in advance due to the fact that the seals quickly become worthless under the influence of coloring substances).

- Specialized repair kit. The kit includes spare parts for spray guns needed to fix a specific problem or replace a failed part.

Malfunctions and how to fix them yourself

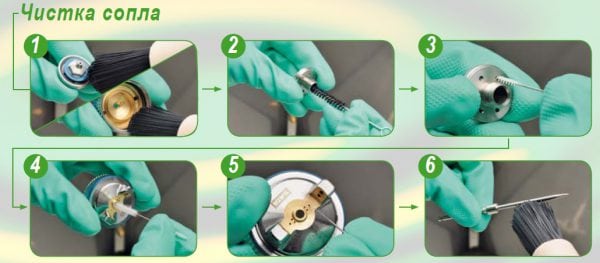

With your own hands, with the help of a set of improvised tools, you can eliminate most of the problems with the spray guns by simply cleaning the nozzle or installing replaceable parts instead of worn out ones.

Hand tool

For manual spray guns, the following problems may occur:

- The coloring mixture begins to boil in the tank, but is not fed to the nozzle. This can happen if the suction valve is clogged. In this case, you can disassemble the unit with your own hands, rinse, clean the valve, and after cleaning install it in place. Or install a new valve from a set of replacement parts.

- Dye is supplied but not sprayed out of the nozzle. There may be two reasons for this:

- The paint has large particles that clog the needle and nozzle. To fix this problem, you can clean the parts or install new parts, and grind the dye solution on a paint grater.

- The filter for the spray gun is out of order. To fix this problem with your own hands, you need to remove the damaged filter, and install a new one in its place.

- The suction valve rises under pressure, but the paint does not flow from the tank, the unit does not spray the solution. This occurs because the suction valve is not seated in its seat due to a clogged filter. To eliminate the malfunction, it is necessary to clean or install the replaceable valve and filter.

- Paint under pressure is not supplied to the nozzle; it is poured through the pump cylinder. This indicates the wear of the stuffing box packing of the pump rod. Depending on the state of the packing, either tighten the fastening nut or install a new packing.

- Weak pressure of the coloring solution with stable operation of the pump in the unit with the lower tank. The reasons may be as follows:

- A small amount of material in the lower container when, with a strong tilt, the suction hose draws air and delivers an air-dye mixture to the nozzle. There is no need for repairs, just add material to the tank.

- The container opening through which the outside air enters is clogged. Then you need to clean not only the air inlet, but also clean the pump hoses.

- The pump has stopped suctioning paint. The reason for this can only be a pump cuff that has lost its quality. It can be softened in oil (if it is dry) or replaceable (if worn).

- The spray gun spits with uneven streams of paint. This occurs when the nozzle for the spray gun has a too large outlet (more than 0.7 mm) due to the washer that has become unusable. To fix the problem, the washer must be replaced using the repair kit.

- Leaking paint from a fishing rod crane. There may be two causes of the malfunction:

- The crane is badly ground. It’s not difficult to fix this problem with your own hands - just grind the tap using tools.

- Spring loosening on the tap. It must be tightened or installed replaceable, using the necessary tools from the repair kit.

Electrical appliance

On electric spray guns, unlike manual spray guns, not all problems that arise can be eliminated with your own hands.

Repair of some of them will require the services of an electrician.

With your own hands, you can eliminate the following problems:

- The dye fence from the tank stopped. As with the manual spray gun, the suction valve must be cleaned to correct this malfunction.

- No solution is supplied from the tank to the nozzle. To restore the dye supply, the needle, nozzle and filter on the suction hose must be cleaned or replaced. Spare parts can be purchased separately or buy a ready-made repair kit.

- The pump does not feed the coloring mixture to the nozzle, sometimes due to improper air pressure or paint supply, after adjusting these parameters, the device starts to paint normally.

- Excessive “bubbling” of material in the container can be caused by air entering it due to improper operation or breakage of the paint head. Using a set of spare parts, it must either be correctly installed or replaced.

- In the tank, when the pump is running, an extraneous knock is heard, which can be caused by a foreign object falling into it or a metal piece breaking off from a moving part (for example, a tooth has broken off from a gear transmission). The container will have to be cleaned, and the subject that caused the extraneous noise should be carefully examined.If this is not a part of the mechanism, then you can install the tank in place, fill the dye and continue to work. But if you suspect that the detail of the moving mechanism has broken off, it is better to turn to the services of a master for inspection and preventive maintenance of the spray gun, and not try to fix the breakage with your own hands.

To eliminate the following problems in the operation of the electro-spray gun, you will need to contact the services of a master in the repair of electrical equipment:

- When turning on the device, no noise is heard from the operation of the electric motor. This happens if the fuses are blown or the breaker is broken.

- When you touch the unit connected to the network, current discharges are felt. Using the device in this case is life threatening, it must be immediately returned for repair. The cause of the failure, most likely, is the closure of the parts responsible for conducting current.

- With strong heating of the apparatus body during operation, timely repair will prevent wear on the parts of the electric motor that occur due to insufficient lubrication between them.

- The unit works, but the pressure gauge does not show that there is pressure. The cause may be a malfunction of the electric pump or pressure gauge.

Tips for extending the life of the spray gun

Spray gun is a complex tool that requires careful treatment. So that he can work for a long time without breakdowns, the following rules for caring for the device must be observed:

- Clean immediately after painting. For this purpose, after removing the coloring material, the tank of the apparatus is filled with a solvent having a composition similar to the dye used, and then the device is turned on and used on an unnecessary surface. The pressurized contents of the tank will make good cleaning of all valves and hoses.

- Never use a solvent that can cause a “chemical conflict” with the staining solution used. Curdled paint residues can damage the mechanism.

- After flushing, the device must be well purged, and the container briefly left open to evaporate residual solvent.

- The spray gun with the coloring compound inside can be left only for a short time, but before that, take the following measures to prevent the composition from drying out: tighten the needle regulator all the way and tightly close the hole from the air entering the tank.

- Before refueling, the gun must be thoroughly blown to remove condensate or accumulated dust.

Most breakdowns of the spray gun can be prevented by properly operating the instrument. But if breakdowns occur, many of them can be fixed independently using repair kits, which include various sets of spare parts and accessories. Timely maintenance and proper care will help the instrument serve its owner for many years.