Using a low-pressure spray gun in the household sphere, it is possible to produce not only do-it-yourself painting and varnishing of surfaces, but also a number of other manipulations. This device is widely used by gardeners for spraying plants, spraying fertilizing and other similar actions.

- Purpose of the tool

- Choosing the right device model

- Pneumatic devices

- Automatic devices

- Self-made atomizer

Purpose of the tool

The decision to use such a tool in their own households was taken by a rather impressive number of craftsmen. Indeed, for this it is absolutely not necessary to spend money on expensive products of famous brands: you can build the thing you need in the household with your own hands using an ordinary household vacuum cleaner.

When planning a quick, high-quality and easy-to-use painting using a special paint sprayer, you should carefully study the quality of the component parts of the device. Considering the fact that processing with such a device is usually carried out on large areas, the reliability and durability of the device as a whole and its individual parts becomes the main requirement at the time of choosing the right model.

Buy spray guns should be based on the upcoming work. Qualified specialists in painting and finishing work can often use up to five devices at a time, which is explained by the features of the treated surfaces, sprayed materials and the area of the objects. Choosing a suitable product should only be done after studying all the requirements for a spray gun for painting work.

to contents ↑Choosing the right device model

Spray guns are represented by a rather rich assortment of modern instruments. Among the existing modifications of spray guns, three main groups of products are identified:

- pneumatic spray guns;

- devices with an electric power source;

- manual spray gun spray gun.

Pneumatic devices

The pneumatic spray gun operates using compressed air. It is this modification of devices that is most in demand in painting various surfaces. Thanks to separate inlets for air and paint, there is a quick mixing of the incoming flows inside a separate air chamber. As a result of the operation of the device, the formation of a coloring torch is ensured, which, due to internal pressure, exits through the corresponding opening of the device under a sufficiently strong pressure.

Analyzing the performance of the spray gun, you should pay attention to the following indicators:

- Spraying of paints is carried out within 400 m2 / hour.

- Application (micro-spraying) of putties - up to 85 m2 / hour.

- Surface and surface treatment for varnishing - from 20 to 50 m2 / hour.

The pneumatic spray gun for paints is produced in accordance with the HP, HVLP and LVLP technologies, which should be considered when choosing the right compressor.

Depending on the production technology, finished products are used in various fields and are designed to carry out several areas of work:

- HP technology. It is the simplest, respectively, products based on it are most affordable and elementary in use. With the help of such a device, the procedure for painting an object with their own hands is quite fast, but not very high quality.

- Device based on HVLP technology: large volume and low pressure. Such pneumatic devices are an upgrade of HP sprayers. The peculiarity is that they have a special structure of the air duct. Such models are characterized by efficiency due to insignificant losses of material. Such paint sprayers have the highest levels of surface coating quality, are excellent for work in most objects, and are used in car painting procedures.

- Paint spray guns with LVLP technology, i.e. low volume low pressure. The youngest technology for these devices is the conversion of HVLP technology. The result of spraying with such a device exceeds all expectations, and the amount of air flow is minimal. Models based on LVLP technology provide 90% of the input material for coating. They are used in coloring cars and trucks both as a whole and in separate parts, in the aerospace industry, in the furniture industry. The structural feature of the LVLP system allows you to work with quick-drying coloring materials.

Automatic devices

Automatic spray guns are widely applicable in the following procedures:

- coloring (repainting) of a car;

- phased restoration of objects and surfaces;

- repair work.

A distinctive feature of such models is their ability to connect to pumps with a diaphragm system or to a pressure tank. The advantages of coatings created by automatic devices are:

- Auto-spraying devices can be used on large-sized objects and large processing areas.

- Automatic devices provide the application of the thinnest layer of material used.

- It is possible to carry out high-precision work, in particular, on the surface of small objects, along the edges, at the joints. In addition, the layer applied with such a tool is characterized by uniformity, density and durability.

Materials for spraying are stains, finishing and restoration varnish, water-soluble paint, adhesives based on water and polyurethane. Often a spraying device is used in the confectionery sector, providing the finest coatings of chocolate and glaze. The most popular models for spray painting are modifications M-10, A-11, A-10, RA-2 and MICRO-3.

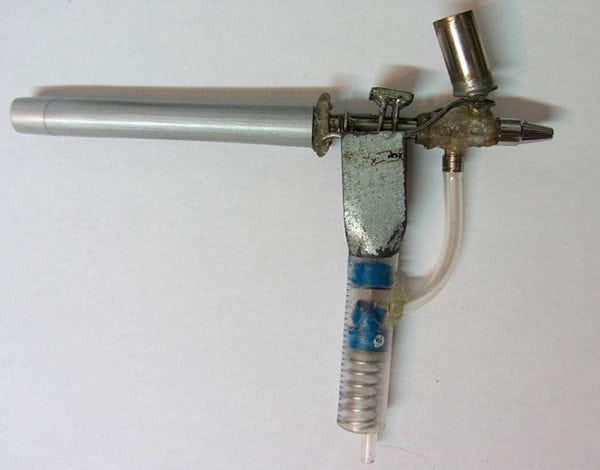

to contents ↑Self-made atomizer

You can build a device for spraying onto the surface of a car or any other with your own hands. In this case, you should make sure that the selected model of the vacuum cleaner is optimally suitable for use as a compressor. An ideal option would be household vacuum cleaners with a reverse blowing mode, which allows you to connect a hose to the other side of the vacuum cleaner. Such features are typical of old Soviet vacuum cleaners: "Whirlwind", "Rocket". It is important that the vacuum cleaner has the pressure at the required high level, and at the end of the work or in case of malfunctions it can be easily repaired.

Old-fashioned models of vacuum cleaners come with their own nozzles, the change of which allows for efficient spraying. Converted vacuum cleaners can do a great job with auto painting.

Following simple guidelines for converting an old vacuum cleaner, you can not only make the necessary device yourself, but also perform a number of finishing or repair work:

- We need a blank from a small piece of foam, which is given the desired shape.

- The shape of the foam piece and the neck of the fluid vessel must be consistent.

- Holes are drilled in the foam, one of which should be made on top of the workpiece, where the rod will be placed. The use of a plastic handle housing is permissible as a rod.

- A horizontal hole is also made and drilled where the rod is installed.

- Bottle caps are used as a stop in a vertical hole.

A paint spraying tool made with a vacuum cleaner is not designed for large-scale work and lengthy manipulations. You can paint auto parts or other small items.

Getting a similar tool in everyday life, you can quite easily do with your own hands manipulations on staining, ordinary painting work, and cope with other tasks that go beyond the field of repair procedures.