Not every spray gun is able to work with a primer. The reason is increased viscosity of primers. Therefore, some models simply do not have enough discharge power or the nozzle diameter is too small. As a result, clogging of the nozzle occurs.

Professional painters in their practice use 2-3 or more specialized spray guns, where each device is designed for a separate front of work. A primer spray gun is one such specialized tool.

to contents ↑Spray gun mechanisms

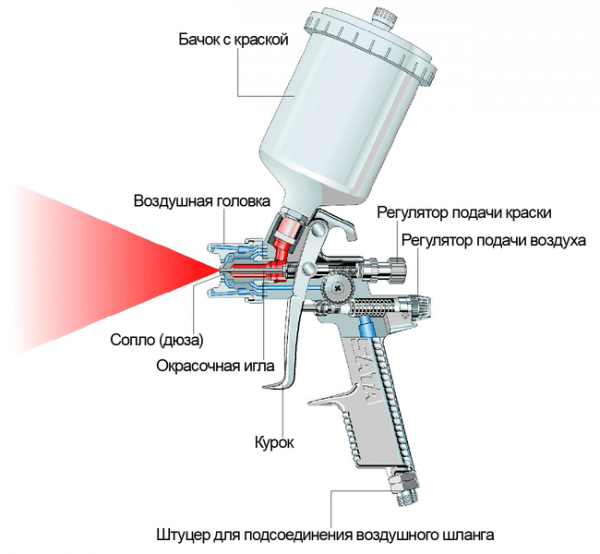

The airbrush consists of the following parts:

- Spray head. This element ensures the spread of the paintwork material on the treated surface. Thanks to the protrusions with the holes made in them, air flows are provided that form the so-called torch (primer flow). In the absence of lateral air flows, the stream of composition will be rounded, and in their presence - elliptical. The amount of air also affects the width of the torch. Control of the torch is carried out by means of a special valve.

- Nozzles. It is a strictly calibrated hole. Dyuza performs several tasks: it doses the flow, gives it direction and acts as a groove for the needle. In some models, a diffuser (deflector) is responsible for the direction of the air-drop flow. For materials with different degrees of viscosity, different nozzles are used, which differ in the diameter of the hole. Typically, manufacturing companies indicate the possibility of using nozzles when working with a particular composition. For a primer, the nozzle diameter can range from 1.4 to 1.8 millimeters.

- Needles. This element allows you to organize a metered supply, increase, reduction or complete shutdown of the flow of paint material. The needle is controlled by the movements of the trigger. The needle must be compatible with the nozzle, as these parts are matched to each other, so each nozzle corresponds to a specific needle, and these parts are usually sold together.

- Cases and sticks. This is the largest part of the spray gun. Devices from the middle and highest price categories are made of aluminum alloy. Moreover, the alloy is a solid piece in which the internal channels are made. Thanks to this manufacturing principle, it is possible to achieve high calibration accuracy. Pistols of the lowest price category are produced by casting, as indicated by the presence of a seam on the body.

- The torch control valve provides control of the air supply to the second air channel. If the valve is open, the airflow moves towards the protrusions, and the width of the torch becomes the maximum possible. With the valve closed, the soil stain will have a rounded shape and small size. The valve may be located on the back of the apparatus above the control valve for supplying paint or varnish material or on the side of the spray gun.

- The soil feed valve is designed to control the amount of material. Also, with its help, you can adjust the flow by narrowing the needle. This element is always located on the needle line on the inside of the spray gun. The valve is controlled by limiting the stroke of the trigger and needle.

- An air valve is located under the trigger. Used to direct compressed air into the channels of the spray gun. The valve can be equipped with a quick connector or pressure gauge.

- The trigger. With the help of a trigger, the process of applying the primer is controlled. After pressing the trigger presses on the air valve, as a result of which compressed air begins to move along the device. If you pull the trigger harder, the needle will move and airflow will pick up the primer.

Spray gun setting

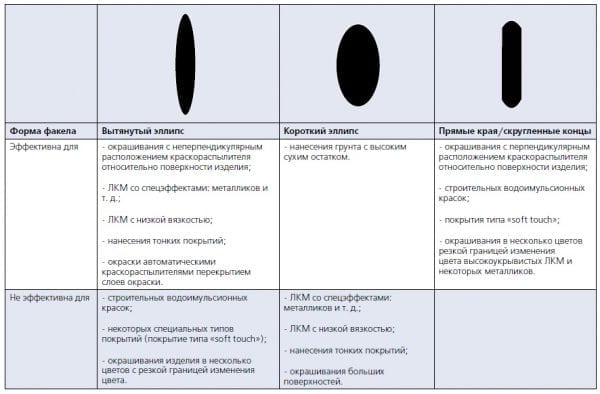

The adjustment process is essential for the quality of priming a wall or other surface. You need to configure the device so that the cone of the torch is of the correct size and shape.

Customization options:

- The shape of the torch is regulated by a special screw.

- The volume of sprayed soil is controlled using the control head. It is recommended that you first apply a little composition to the probe before applying it to the final surface. This will help estimate the amount of material released.

- The pressure level is set using the adjustment head of the bore. The recommended pressure indicator is 3-5 bar. Also, using the head, you can change the shape of the cone of the torch.

The nozzle is crucial for high-quality priming. The greater the grit of the primer, the larger the nozzle diameter should be.

Spray gun DeVilbiss PRI Pro

Especially for working with primers, the American company "DeVilbiss" has developed a model of the spray gun "PRI Pro". The spray is designed to work with highly viscous compounds, including those based on water.

The device operates by spraying the soil at an overpressure of compressed air.

Advantages of the primer sprayer "DeVilbiss PRI Pro":

- Adaptability to viscous compounds.

- The ability to work with any type of soil, including the latest generation water-based compounds.

- The sprayer can work not only with primers, but also with any kind of paint, including dilute organic solvents.

- The size of the nozzle allows you to work with fillers, putties, polyester substances.

- Rational distribution of air flows and materials in the flare.

- Trans-Tech technology reduces fogging and excessive material consumption.

- The material transfer rate reaches 88%.

- The air valve allows you to smoothly control the torch.

- Excellent spray angle.

- Well-thought-out ergonomics - the case is ideally fitted to the hand controlling it.

- Simplicity of operation.

- Thanks to anodizing, the casing is suitable for working with water-based materials.

- Fame and recognition among professionals.

The set of equipment includes:

- primer spray gun;

- top tank with filter for paint or primer;

- quick-detachable joint for air hose on hinges;

- wrench;

- brush for cleaning mechanisms.

Specifications:

- Inlet air pressure - 2 bar.

- Air consumption - 350 liters per minute.

- Universal thread at the inlet of the air flow - 1/4 ″.

- The tank capacity is 560 milliliters.

- The weight of the device is 768 grams.

- The material of which the air head and ring are made is a brass alloy with galvanic coating.

- The material of the nozzle and needle is stainless steel.

If desired, you can configure to work with soil and a standard spray gun. However, versatility is far from always compatible with the high quality of work performed.Therefore, if it is not a one-time primer, but a large and constant amount of work, professional equipment is indispensable.