The most convenient and therefore popular device for spraying paint is an airless spray gun. This is a necessary device in auto repair shops, industrial premises and just at home. If you want to achieve the perfect result when applying a paint and varnish coating, then this unit will perfectly cope with this task.

Features

Compared to brushes or rollers, which are most often used for painting, this unit helps to perform all decorative coatings much faster and with less effort. Depending on the spraying method, airless, pneumatic and combined devices are distinguished. They are also classified according to the type of drive used: there are electric and manual ones. According to the method of application, they are divided into stationary and manual.

Manual equipment has a lower cost, so it is widespread. For ordinary paint work this spray gun is ideally suited. The stationary spray gun is often used by professionals. It has a high cost, suitable for coloring complex curly elements or for performing extensive projects.

As for the principle of action, it is quite simple in an airless spray gun. TOthe paint that is in the tank is passed through a nozzle installed in the device. After that, it is crushed and fixed on the necessary surface. The crushed small particles dry much faster and are better distributed on the surface.

Sometimes it’s difficult for a layman to understand this principle of the device’s operation, therefore it can be explained even easier: the device is a pump that works with the help of an engine. Through a hose, paint or other material enters the nozzle where crushing occurs. Then it is sprayed under high pressure.

Using this method, it is very convenient to apply materials such as:

- alkyd;

- latex;

- epoxy;

- fire retardant;

- textured.

This equipment works from the network, that is, it is electric.

The required voltage depends on the selected model and can be 220 or 380 volts.

What the apparatus should be must be decided on the basis of the purpose for which it will be used.

to contents ↑Airbrush device

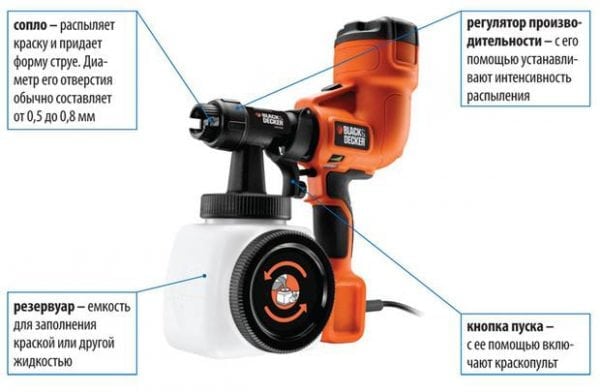

The device consists of a housing, which can be made of aluminum or plastic. If you are poorly versed in spray guns and do not know which one is better to choose, then it is necessary to pay attention first of all to the presence of a safety system. In addition, there must be a filter in electrical equipment. If it is of high quality, then small particles of paint will not get into the air. The term of use of the device largely depends on the filter.

In addition to the safety system, a special clip must also be present to prevent accidental trigger pulling. This device must have a handle. A non-slip surface is usually applied on it - it is very important that during the work it lies comfortably in the hand. Its length, as a rule, is about 15 cm. For this method of application, this is the best option.

In some models, there is also a swivel mechanism that works on the basis of a drum.With its help it is much easier to produce rotational movements.

to contents ↑The working process

To use this spray method, the equipment must be set up correctly. Otherwise, the desired result cannot be achieved. Before work, it is necessary to adjust the spray gun and be sure to check its effect on a newspaper or sheet of paper. To do this, pull the trigger and try to spray the composition. After large streaks of paint form, stop pressing and observe their condition.

In the event that the device was set up correctly, excess paint will begin to flow down evenly. If uneven spreading is detected, it is recommended to change the consistency of the mixture or the pressure in the atomizer. If heavy drips appear during operation, the pressure must be weakened. If the paint stain is not bright enough, then you need to make the material not so viscous, preferably with a solvent. After that, you can proceed directly to work.

Professionals recommend tilting the spray gun to the right, left, as well as lowering and raising it. This method will allow to achieve high-quality staining of any element. After completing all the work, it is recommended to clean the equipment well so that even small grains are not left in it. After cleaning, it must be lubricated with a special agent, which should not contain silicone.

to contents ↑Pros and cons

Most surfaces can be painted without using a spray gun, however, this method does not guarantee a good result. Airless sprayer has the following advantages:

- The composition is crushed to the smallest particles, so it is realistically possible to stain even in hard-to-reach places, where it is impossible to do this using the manual method.

- Due to the fact that the equipment works automatically, you can perform a large amount of work in a short period of time.

- Due to the fact that the application occurs without contact with the surface, stains and stripes do not appear.

- It is better to use a spray gun because even on an inhomogeneous surface the color will look as even as possible.

- Significantly simplifies the workflow, is used when painting even large volumes.

- Depending on the task, you can choose the method of spraying - a narrow strip, a spot, a dot or with different thicknesses. You can choose the method of spraying by installing the necessary nozzle.

Sag and drips can occur only if you do not know which tip is best to choose for the intended purpose. A lot also depends on the spraying speed. With experience, you will learn how to regulate it in time. In rare cases, drips appear when processing paint with complex shapes, but even then with the help of an electric spray gun it will be possible to correct everything. Non-professionals master this equipment quickly enough, so over time it will be possible to learn how to work as a professional painter.

Of the minuses of this equipment, it should be noted that during spraying a small cloud appears, which consists of small particles of paint. Therefore, when using the airless painting method, it is necessary to prepare the room in advance. Otherwise, the paint may remain on objects or other walls.

Some owners also consider the disadvantages that the equipment needs special care and that after each use it needs to be washed and processed. For this process, you will also need a solvent and a special tool, which will have to spend money.

When choosing an airless spray gun, make sure that all seals and ducts are tight. Now you can choose the best sprayer option for yourself and quickly complete the necessary work.

What to rinse with an airless spray gun (in my case wagner ps 3.20) included a special flushing liquid in a 4 liter bottle of WATER; at one time, God forbid, the instructions say that you don’t want to ditch high pressure hoses in a solvent