Liquid nails are a popular type of construction adhesive. They are compatible with almost all materials used in construction and repair, durable, tightly connect surfaces and close joints. Liquid nails are especially well suited for PVC panels, plates, sheets, which often finish dry and wet rooms, and sometimes they are also used for outdoor applications.

- PVC panel mounting options

- The choice of adhesive

- Varieties of Liquid Nails

- Installing plastic panels on liquid nails: important steps

- Preliminary work

- Installation of PVC panels on the wall

- Basic installation errors

- How to glue PVC panels on the ceiling in the bathroom?

- Advantages and disadvantages of fastening PVC panels to liquid nails

- What glue to use?

- Kleiberit

- Glue Titan Wild

- Liquid Nails Quality

PVC panel mounting options

All methods of attaching panels made of polyvinyl chloride (PVC) to the wall can be divided into frame and adhesive. The first group is more time-consuming, and when using metal profiles will be quite expensive. If the walls are uneven, it is better to choose the frame methods when PVC panels are mounted with nails, screws, brackets on a pre-prepared metal or wooden crate. Thus, you can not only securely fasten the panels, but also hide any defects in the base or wiring. The disadvantage of this method is that the crate takes up free space - at least 3 cm from each wall, which can be significant for a small room.

The glue method for fastening PVC panels is the use of liquid nails, which are applied to the inner surface of the material and firmly fix it to the wall. The base should be even, otherwise the panels will not hold firmly, and all the flaws of the walls will become even more noticeable. This method is ideal for well-prepared, leveled surfaces in a small room where every centimeter of area is important. Also, gluing on liquid nails is well suited for large plates, since the method allows you to act carefully, without damaging the canvas.

to contents ↑The choice of adhesive

When buying, it is important to pay attention to the suitability of liquid nails for working with polyvinyl chloride. Most compounds are considered universal: they are suitable for all materials, because they are made on the basis of artificial rubber, which does not damage the surface and does not react with them. Nevertheless, some liquid nails have special properties that give their action specificity.

This is always noted on the packaging:

- for internal use only;

- for outdoor or landscape work (with increased frost resistance);

- for wet rooms;

- for mirrors (do not damage the amalgam);

- for foam panels;

- heavy-duty for heavy panels;

- for wood and MDF panels;

- roofing.

The best solution is to buy glue, the instructions for which clearly state the possibility of using it on plastic, including PVC. Also, liquid nails should not damage the base material (wood, brick, plaster, concrete, stone, drywall, particleboard and others). If the walls are being finished in the bathroom, the adhesive must be suitable for rooms with high humidity, withstand contact with water and not be destroyed by detergents, alkalis. Other requirements for high-quality liquid nails for working with PVC:

- transparency after drying or white color depending on the type of panels (usually selected by the color of the cap);

- resistance to temperature changes, frost resistance (if you finish the terrace, balcony, other external buildings);

- high degree of adhesion with any base;

- long service life (up to 15–20 years);

- the presence of an antiseptic and fungicide in the composition;

- elasticity, lack of cracking during deformation of the base;

- reasonable price, economical expense;

- convenient application with a gun.

The glue must be quickly set, because holding each panel for a long time is difficult and inconvenient. It is desirable that the product is environmentally friendly, does not emit toxic compounds and unpleasant odors, otherwise after installing the panels you will have to ventilate the room for 1-3 days. Liquid nails with a viscous, dense texture are considered to be more convenient in operation, which do not spread on PVC, but quickly set and securely attach to the base. Only with thick glue can you fix the panels on the walls, slopes, door and window openings, decorate the interior in the right way.

Varieties of Liquid Nails

There are two types of liquid nails on the market:

- Neoprene. Made on the basis of polyurethane with the addition of organic solvents. They provide instant bonding of surfaces, tightly couple them, serve for a long time, are not afraid of water and any chemicals, ultraviolet radiation. Suitable for rooms with constant temperature changes and high humidity. Due to the presence of solvents, they are toxic until dry (then safe for humans), and an unpleasant odor is released.

- Acrylic Absolutely not hazardous to health, water-based, but have a lower degree of adhesion to the bases. They have average water resistance compared to the first options, therefore, for the installation of panels in the bathroom are undesirable. Such liquid nails are also more sensitive to temperature differences, as well as to the action of aggressive substances.

to contents ↑When working with neoprene liquid nails indoors, it is imperative to use personal protective equipment: a respirator, glasses, gloves, and also provide good air ventilation.

Installing plastic panels on liquid nails: important steps

To achieve a long-term result, you need to qualitatively prepare the base, and only then proceed with the installation of PVC panels.

Preliminary work

The wall on which the panels will be attached must be flat, otherwise in some places the material will lag behind the surface and will not last long. Preparation is carried out according to the following steps:

- Removing the old coating. Remove wallpaper, peeling plaster and putty, paint that has already begun to crumble. Without this, the old finish can come off under the weight of the panels with them. When there are signs of mold on the surface, they are sanitized by special means (they wipe the place with a liquid 2-3 times).

- Alignment of the base. Holes are covered, deep cracks are reinforced with a net, and then putty. When peeling off the plaster, remove it, cover the problem area with 2 layers of primer, putty thinly, then a reinforcing canvas and a new layer of building mixture. After the elimination of large defects, the entire surface is leveled to eliminate differences. If the wall is severely curved, you will have to use the crate method.

- Padding. The base is coated with 1-2 layers of primer to enhance adhesion to PVC panels and reduce the consumption of liquid nails. If the work is carried out in the bathroom, it is important that the composition contains anti-mold additives.

You can start finishing work after the primer dries - this process can take 6-12 hours.For ease of installation, markup in the form of lines should be applied every 30-50 cm (depending on the size of the panels) horizontally or vertically. The lines are drawn according to the level with a construction marker or pencil, so that the finished surface is smooth and beautiful.

to contents ↑Installation of PVC panels on the wall

In addition to the required number of PVC panels and glue, tools and supplies are prepared for work:

- construction gun;

- level;

- bucket with water;

- sponge to remove excess glue;

- joint sealant;

- solvent;

- rubber roller.

Panels must be cut in accordance with the layout and layout of the finish. The process is carried out strictly from the front side, which will avoid the appearance of edges and fringes on the outside. A slice made from the inside turns out to be smooth and accurate. If, in addition to the panels, corners framing the profiles are purchased, first they are glued according to the marking under the control of the building level.

Further, the procedure is as follows:

- to improve adhesion, degrease the underside of the panels with a solvent (this step can be skipped, but with its implementation, the quality of gluing will increase);

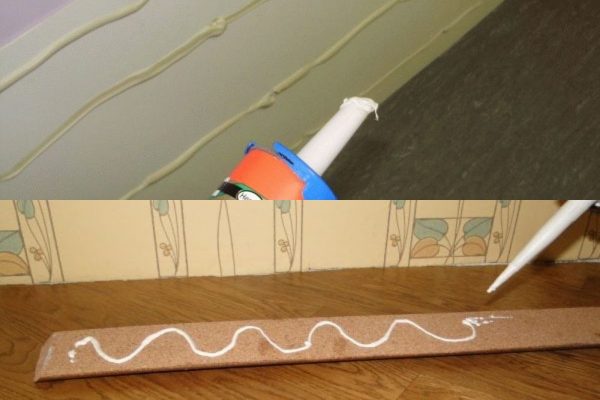

- apply the composition to the wall or panel in a zigzag or dot pattern after 30 cm (if the panel is heavy, reduce the distance between the points);

- put the panel in place, press it firmly against the wall, adjust its location during the first 1-3 minutes;

- thin panels are rolled with a rubber roller;

- periodically check the evenness of bonding elements using a building level.

Strong setting is achieved after 15–20 minutes, and complete drying takes 1–2 days, depending on the type and brand of liquid nails. After the glue dries, a transparent silicone-based sealant is used to seal the joints between the panels and the ceiling, as well as in other places where there is a risk of water leakage. This will smooth out the ugly gap and increase the tightness of the connection.

If by mistake liquid nails were applied in excess and the composition begins to seep between the seams of the panels, it must be removed immediately. After drying, this will be problematic. Wipe the product with a sponge dampened in water, or carefully use a solvent.

If necessary, plastic panels can be glued to liquid nails, even on the crate. This is easier to do than drill them into screws. The principle of operation will be similar, the only difference is that the composition is applied to the profile pointwise with a small distance. If the panels are heavy, liquid nails are applied to the profile with a solid line.

Basic installation errors

Inexperienced masters often make erroneous actions that lead to poor-quality results. Here are the most common flaws in working with PVC panels:

- Bending panels. If you twist, deform the product, it will crack, or an ugly strip will appear on it. Subsequently, this will affect not only the external attractiveness, but also the life of the PVC.

- Temperature difference. To securely adhere the panels, they are brought into the house in advance and allowed to warm up at room temperature. If you take the cold panels from the balcony and immediately begin to glue them, liquid nails can soon move away from the surface due to poor adhesion. The temperature of the glue and the base material during operation should be approximately the same.

- Poor preparation. Saving time and money on anti-mold processing, removing dust, dirt is not the best solution. The panels will detach from the walls quite quickly, especially in conditions of high humidity and temperature changes. Foci of mold will form under them, which is harmful to the health of residents.

- Early removal of the protective film. When installing “bare” panels are often scratched, stains from liquid nails may go unnoticed on the front side. To prevent this from happening, remove the protective film only after the completion of all installation work.

- Unsuitable glue. Do not replace liquid nails with superglues, PVA, or expired products. This will quickly detach the panels.

How to glue PVC panels on the ceiling in the bathroom?

Attaching plastic to glue is the most convenient way to install it in a small bathroom, where the ceiling height does not allow the installation of more complex structures. For work, you will need the same materials and tools, as well as a stepladder, to make finishing with convenience. As a preparation, the ceiling is cleaned of the old peeling coating, the cracks are smeared, the surface is primed.

Installation begins with measuring and marking the ceiling with a marker or pencil, after pulling the twine on the diagonal and highlighting the center at the point of intersection. After marking, the panels are greased with a continuous layer of glue (smooth the liquid nails with a spatula), applied to the ceiling. The first element is always mounted in the center, then in parallel rows. Excess funds are immediately removed with a damp sponge. The ceiling edge is decorated with corners, baguettes, and at the place of lighting they put a decorative outlet.

to contents ↑

Advantages and disadvantages of fastening PVC panels to liquid nails

The use of liquid nails for decorating walls with plastic panels has many advantages:

- glue does not damage PVC, does not cause damage to walls;

- the position of the panels can be adjusted in time;

- liquid nails do not require additional mechanical fastening - they themselves reliably hold the material;

- glue is not damaged by aggressive factors, it lasts a very long time;

- the use of liquid nails will save time on the installation of the lathing, it will not cause concealment of the useful area, which is important for small rooms

- lining can be done in a matter of hours, there is no need to build complex structures, purchase tools for cutting metal, invite assistants.

There are also disadvantages to this installation method. Neoprene nails, which are recommended for fixing PVC, are not environmentally friendly: they emit a pungent odor and are harmful to health. Work with them only with the observance of individual security measures. The room will have to be ventilated for several days, which is often difficult, especially in winter. If the walls have sharp changes, the use of liquid nails is impractical - the plastic will peel off from the base.

to contents ↑What glue to use?

The quality of the entire finished decoration often depends on the brand of glue, so it is better not to save and buy compositions of well-known manufacturers.

Kleiberit

Synthetic resins are the basis of liquid nails of this brand. The product includes solvents, is not afraid of humidity, temperature changes, uniform and viscous. The composition dries quickly, powerful, even sticks wide sheet panels.

to contents ↑Glue Titan Wild

This is a universal tool for working with plastic, concrete, metal, wood and other building materials. It has a high degree of adhesion, is very resistant to temperature extremes, suitable for wet rooms. It can be used even for outdoor use.

to contents ↑Liquid Nails Quality

It is considered a professional composition for construction and decoration. White, well suited for fastening PVC panels. It dries quickly and seizes almost instantly, so the material does not have to be held for a long time by hand.

Installation of PVC panels on liquid nails is an excellent solution for those who value their time, want to make repairs in the bathroom, kitchen, on the balcony quickly and inexpensively. The cladding will last a long time and without complaints, so if you have even walls, you can safely use liquid nails to install panels.