When performing construction and installation works, an important condition is to ensure the tightness of all joints and joints. Among professionals, Sazilast-24 sealant is in great demand, as well as a number of other compounds of this brand.

- Features of sealants

- Varieties

- Specifications

- Life time

- Installation instructions

- Surface preparation

- Thermal insulation layer

- Sealant preparation

- Sealant Application

- Safety precautions

The manufacturer - the company "SAZI" - has been producing sealing products for more than 25 years and is considered the largest supplier in the Russian Federation, and some materials are even suitable for use in the aerospace industry.

Features of sealants

The line of Sazilast sealants is quite extensive and includes several products with different properties, composition, and technical characteristics. The most famous sealant is Sazilast-24, made on a polyurethane basis. Most sealing materials are considered universal, suitable for exterior and interior use, as well as for application to damp substrates.

Features of brand sealants are as follows:

- neutrality to the influence of acids, alkalis, ultraviolet radiation, oils;

- water resistance and water resistance;

- tolerance of vibration and other types of mechanical stress, temperature extremes, high humidity;

- long service life (from 15 years);

- the possibility of application on the floor, walls, facades, roof, for closing joints, seams, cracks when working with all building materials;

- application at positive and negative temperatures;

- good interaction with paint, plaster;

- admissibility for work with deformable substrates (at a deformation level of up to 15-25%).

Varieties

Sealants are available in tubes, cartridges and pails weighing up to 15 kg. The most popular Sazilast-24 polyurethane sealant is produced in three versions:

- "Classic". A universal tool for sealing joints in panel house building, easily tolerating coating deformations. Designed for a wide range of operating temperatures (–60 ... + 70 degrees), ideally adheres to concrete, foam concrete, brick. It is conveniently put, it is presented in white and gray color. It has a two-component form (paste and hardener).

- "Comfort". Universal sealant for application at –15 ... + 50 degrees. A feature is the tearing of the product from the base with short threads, as a result of which it does not reach for the adhesive tape when removed.

- "Snowflake". Due to the presence of modified plasticizers, the components of this sealant can be kneaded and applied at low temperatures (up to –20 degrees). It is quite viscous and does not flow down from vertical seams.

Another popular product is Sazilast-25, a two-component polyurethane curable sealant. It is used to seal expansion joints of concrete and other building structures, which are subject to shear by no more than 25%. After hardening, sealed joints can be painted with any composition based on organic solvents.

Other brand sealants that can be found in hardware stores:

- "Sazilast-9" - contains hybrid polymers, thixotropic, has high elasticity, can be used on facades and indoors;

- "Sazilast-22" - a curing thiol-containing sealant with low viscosity, not subject to staining;

- "Sazilast-21" is a polysulfide composition with increased resistance to UV radiation and weathering, suitable for metal works;

- “Sazilast-13” is a one-component polyurethane material in the form of a “sausage”, has a high resistance to runoff, is suitable for metals and alloys;

- Sazilast-503 is a polysulphide two-component sealant with increased adhesion to concrete, glass, brick, as well as high resistance to UV and aggressive substances;

- "Sazilast-502" - pouring polysulfide sealant for sealing joints of elements of different designs with a low modulus of elasticity;

- "Sazilast-51" is a thiokol curing composition with high resistance to runoff for sealing roofs, attics, communications;

- “Sazilast-53” is a two-component polysulfide composition for working with elements of roads, sewers, joints in concrete products.

Specifications

Depending on the composition, the technical parameters of sealants vary. Nevertheless, most of them are suitable for working with concrete, stone, brick, roofing materials, some do not cause corrosion, therefore they are suitable for metal substrates. Sazilast-24 Classic has the average technical characteristics:

- appearance - homogeneous paste of white, gray or light beige color;

- type of curing - vulcanization with the participation of a crosslinking agent;

- solidification time - 48 hours at room temperature;

- viability of the product - 6 hours at +23 degrees;

- density - 1.7 g / cu. cm;

- elongation at break - 300%;

- tensile strength - 0.2 MPa;

- modulus of elasticity with elongation of 100% - 0.4 MPa;

- fluidity - less than 2 mm;

- Shore A hardness - 20 units after 24 hours.

Life time

In most formulations, the life time after mixing the components is 6 hours. With decreasing temperature, it lengthens, with increasing it decreases. The warranty shelf life of unopened packaging is 6 months, provided that it is stored at a temperature of –20 ... + 30 degrees. Moisture must not be allowed to enter the hardener or base composition.

Installation instructions

To work with sealant, a low-speed drill with a blade nozzle, a rubber or metal spatula, construction adhesive tape, a hair brush, a wooden spatula will be required. For single-component compositions, it is not necessary to mix the components, therefore, a drill is not needed.

Surface preparation

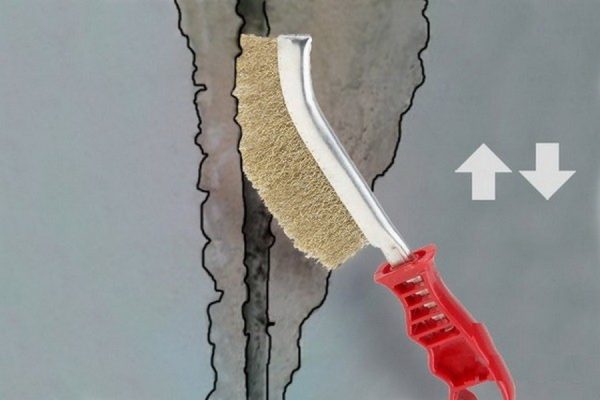

The base before work must be well cleaned of any dirt, brush out the dust, remove adhering mortar, old sealants, paint with a spatula, and on the outer surfaces snow, ice. The presence of obvious drops of water on the surface is not allowed, although it may be slightly damp. To make beautiful seams, it is advisable to paste over the edges of two joints with masking tape.

Thermal insulation layer

For arrangement of thermal insulation it is necessary to use special sealing plaits of the Isonel type made of foamed polyethylene. They significantly reduce the thermal conductivity of the walls and increase the adhesion of the material to the sealant. The latter does not stick together with the cord due to low adhesion to polyethylene, therefore, when the surfaces are deformed, the risk of damage to the entire insulation layer is reduced. This sealant compares favorably with polyurethane foam, therefore, it is preferable to use.

The tourniquet is placed in dry horizontal or vertical joints on the outside of the wall, without stretching it to the sides. For the convenience of introducing the tourniquet, they take a wooden spatula with a rounded shape. On average, each bundle should be crimped in the seam for 20-50% of the original volume.

Sealant preparation

When connecting the components of two-packaging products, it is important to strictly observe the proportions recommended by the manufacturer. If there is too much hardener in the composition, the sealant will lose strength. When curing fluid is added in less than necessary quantity, the sealant remains sticky or does not harden at all. When mixing the components in winter, you must first keep them warm for at least a day.

After pouring the hardener into the main composition, the mass is thoroughly mixed with a drill at low speeds. The remnants of both products on the container walls must be removed with a spatula and also added to the mixture, then mixed again. The total duration of the “whipping” of the sealant should be about 10 minutes, until the mass becomes homogeneous, homogeneous.

Sealant Application

The tool is introduced into the seam with a spatula, observing a layer thickness of 3 mm or more. If the seam width is over 4 cm, then the sealing is carried out in 2 stages. First, the tool is applied at the edges, then at the center of the joint.

Safety precautions

Sazilast sealants should be prevented from getting on the skin, mucous membranes. To prevent this from happening, one must work with gloves, a mask, and glasses. If the composition gets on the skin, it is important to immediately wash the area with soap. Tools after work are easily cleaned with acetone, white spirit.

Sealants "Sazilast" are real helpers to the masters. They are useful for building and repairing private and apartment buildings, restoration and construction of other structures. Given the variety of formulations, you can easily choose the right sealant for a particular situation.