Loktayt sealant is an excellent solution to a wide range of tasks. Due to its unique composition, it is suitable for gluing / sealing joints and various surfaces.

- A bit about Loctite

- Varieties of compositions

- Threaded locks

- Thread sealants

- Flange sealants

- Industrial sealants

- Shaft / sleeve retainers

- Popular materials

- Loctite 5900

- Loctite 290

- Teroson MS 9220

- Application Rules

A bit about Loctite

The sealant went on sale in the middle of the last century and quickly gained the trust of people. Consumers praised its quality and performance.

The creator of this tool, the chemist Vernon Cribble from Harford (Connecticut, USA) experimented with ester polymerization inhibitors. He wanted to achieve curing in an airless space, as a result of which anaerobic adhesive appeared.

Further work led to the creation of a material called the “liquid lock nut”. It allowed to remove the problem of unscrewing and provided high-quality and durable fastening. This was an excellent solution for securing threaded joints securely.

So Loctite appeared. In the course of subsequent experiments, the range of sealants expanded significantly, as well as additional funds with similar or different indicators. An example is the world famous superglue. The compositions were created on a diverse basis:

- epoxy;

- acrylic;

- silicone.

The world saw cyanoacrital and anaerobic drugs with a wide spectrum of action. An important achievement was the polymerization of single-component compositions, which allowed to expand the scope.

Another development spiral was set in 1997, when Loctite was acquired by the world famous Henkel concern. The corporation retained the original name of the sealant, but made it even more reliable, practical, durable and affordable.

to contents ↑Varieties of compositions

The variety of the entire Loktayt sealant range is striking. On the shelves of construction / hardware stores you can find compounds marked with the following values:

- 518

- 574

- 577

- 5699

- 5900

- 5910

- 5920.

The rich assortment has led to the popularization of the product, and now Loctite is actively used to solve various problems. It is suitable for industrial and private needs, and its reasonable price makes it affordable for a wide range of consumers.

to contents ↑Threaded locks

These formulations prevent self-screwing of hardware. They are used for reliable and quick connection of fasteners, providing excellent sealing.

The main advantage of semi-solid and viscous products is that they fill all the available space, eliminating the possibility of leakage of liquid and gaseous media.

Polymerization occurs at room temperature. Threaded fasteners are great for working with metal compounds, as they are known for high adhesion. Other advantages of these tools include:

- resistance to vibration;

- durability;

- practicality of the connection;

- effective elimination of leaks on various threaded connections;

- wide range of operating temperatures.

Among the entire model range, the most popular are compounds with the marking:

- 243;

- 270;

- 2400.

Loktayt sealant is known for economical consumption. Threaded locks are easy to apply and do not require additional devices.

to contents ↑Thread sealants

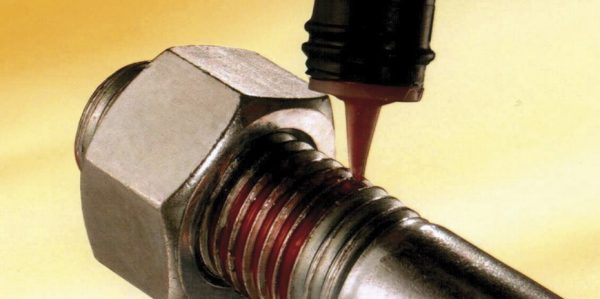

They deserve the most attention. Having a special composition, these tools provide complete sealing on the thread. Liquid and gases do not leak even through small cracks and openings, which allows you to do without FUM tape, tow and other devices.

Loctite provides reliable sealing of threaded joints. A liquid, but moderately thick consistency qualitatively fills the gaps, excluding leaks.

The advantages of Loctite sealant for threaded connections include:

- preservation of properties at elevated temperatures;

- low pressure after application;

- excellent resistance to stress after full cure.

For ease of use, this composition is available in the form of a sealing thread. Loktayt anaerobic sealant polymerizes even in airless space upon contact with metal. Silicone cures at room temperature. This contributes to the moisture contained in the air.

Loctite is classified by application:

- anaerobic - for metal pipes;

- silicone - for plastic threads;

- sealing thread - for conical joints made of metal and plastic.

Flange sealants

As the name implies, these tools are designed to seal flange joints. They are used in many utilities, including water and gas pipelines.

The Loctite 518 sealant acts as an impermeable gasket. Due to the expansion properties and good adhesion, it creates a reliable barrier between the metal flanges without harming their fastening.

Of the advantages of this tool, you need to highlight:

- resistance to high pressure of the medium in the highway;

- high-quality and quick sealing without residual shrinkage;

- tightness of the coating;

- immunity to aggressive environments;

- uniform filling throughout the available space.

Flange sealants are more effective than ordinary gaskets. The long service life and the absence of the need for regular replacement speaks in their favor. Loctite does not deform (the seal does not break) under heavy loads on the flange joint. In solid form, it does not go beyond the boundaries of the region even with strong pressure, which is constantly observed in engineering highways.

An important role is played by damage resistance:

- breaks;

- abrasion;

- cracking.

The practicality of these products is also affected by a wide range of operating temperatures: from –55 to +150 degrees Celsius. Loktayt sealants 5188, 574 and 518 are suitable for steel, cast iron and aluminum flanges, and red in the syringe is ideal for sealing joints in automobiles.

to contents ↑Industrial sealants

Industrial facilities are known for good performance. Loctite 5145 is able to withstand the displacement of several parts, without violating the density of the connection. Known for high adhesion and long life. These qualities make Loktayt products indispensable for industrial needs.

The scope of these tools is wide. Sealants are used to seal the nodes, as well as when connecting various parts in complex mechanisms.

One- and two-component industrial sealants prevent moisture, gases, steam, and small particles from entering the joint. In addition, they are known for the following characteristics:

- good adhesion to most modern materials used in industrial needs;

- weather resistance;

- durability, and aging is not accompanied by deformation / cracking;

- immunity to caustic and aggressive chemicals.

Industrial sealants are silane-modified and butyl. Means of the second type have good adhesion even to glass, ceramic and other smooth surfaces.

to contents ↑Due to its high consumer qualities, industrial Loktite sealants are suitable for modeling / assembling light structures, reducing production costs and increasing the pace of work. They allow to do without additional fixing devices.

Shaft / sleeve retainers

Loctite sealants in this group are designed for the rigid fit of cylindrical automotive parts, including shafts, bushings and bearings. Having good binding properties, sealants provide a reliable connection of the node and increase its bearing capacity.

The widespread use of these tools is also due to the correct distribution of the load throughout the node. This ensures the safety of mechanical components and reduces the likelihood of premature wear.

Sealants made on the basis of methacrylate are known for the following features:

- perfectly fill the gap;

- protect metal products from the harmful effects of moisture and prevent the development of corrosive processes;

- reduce mechanical fatigue of parts and increase the life of the entire assembly.

to contents ↑Means Loctite 660 is in greatest demand among the line in question. This sealant has an activator, so that full technological strength occurs 15 minutes after application. When cured, it forms a layer with a thickness of 0.5 mm.

Popular materials

The product line is very diverse, as is the price range. This allows you to choose the right tool for each task or to find a universal composition of a wide spectrum of action. For convenience and easy orientation, it is worth considering several of the most famous models.

Loctite 5900

The popular one-component sealant in black. It freezes at room temperature. Known for increased resistance to engine oils. Of the advantages it is worth highlighting:

- lack of shrinkage and corrosion;

- wide temperature range - from –55 to +200 degrees Celsius;

- hardening at room temperature.

The sealant is intended for hydraulic and pneumatic connections. Suitable for filling threaded metal assemblies that have small gaps.

to contents ↑Loctite 290

Known thread lock with low viscosity and good strength. It has a lower temperature range than the Loctite 5900, but it prevents the weakening of the alignment of elements and the formation of leaks in the site. This sealant is suitable for connections of type M6 and is actively used in carburetor screws, as well as in instrumentation.

to contents ↑Teroson MS 9220

Another equally popular tool that deserves attention. Structural MS-polymer sealant has a one-component composition (cures upon contact with a humid environment). It has a characteristic black color and is used in the production of:

- automotive technology;

- railway wagons;

- semitrailers;

- sea vessels.

to contents ↑Teroson MS 9220 is characterized by excellent adhesion with galvanized steels, Teflon, glass, aluminum and other materials. Withstands short-term exposure up to +120 degrees Celsius.

Application Rules

Before applying Loktayt sealant, it is necessary to completely clear the surface of dust, dirt, moisture and oil stains. To remove carbon deposits, you can use a stiff brush, as well as various degreasers.

Further it is necessary:

- Put the tube into the gun.

- Squeeze out the gel and apply it evenly to the surface.

- Press the product firmly.

- If necessary, carefully remove excess sealant.

In the professional field, a syringe sealant is often used. It is applied without a gun and immediately ready for use. Such a tool is indispensable for service stations. Before further use of the mechanism or assembly, make sure that the sealant has completely hardened and is ready for use.