To connect the various parts of the engine, special sealants are used that meet all the necessary requirements. For example, the sealant for the valve cover is forced to work at high temperature, undergoes contact with motor oil - a rather aggressive substance that can destroy polymer compositions over time. However, it is necessary to use a sealant, otherwise the valve cover will leak oil, and the engine will need serious repairs.

- When do I need to change the gasket?

- The main types of cylinder head gaskets

- Types of sealants

- Valve Seal Requirements

- Overview of popular sealants

- Black heat resistant DoneDeal

- ABRO 11 AB

- Victor reinz

- Dirko

- Permatex Anaerobic Gasket Maker Anaerobic Composition

- CYCLO HI Temp C 952

- Curil

- MANNOL 9914 Gasket maker RED

- Other popular brands

- How to use valve sealant?

- Preparation and installation of cylinder head gasket

When do I need to change the gasket?

Any engine has a valve cover that attaches to the cylinder head with a few bolts. Between the cover and the head is a rubber gasket that can withstand sudden changes in temperature and exposure to process fluids. Over time, the gasket wears out - its elasticity decreases, small cracks appear. As a result, the oil begins to leak into the engine compartment, after which dust and dirt adhere to the spots.

To avoid the appearance of stubborn stains, it is necessary to timely change the gasket and monitor the condition of the engine as a whole. It is usually recommended to do this after 7000-15000 km of run, which virtually eliminates oil leaks and is the prevention of problems with the engine and timing belt. There are other situations in which it is necessary to change the rubber gasket (usually together with the repair of the cylinder head (cylinder head)):

- Burnout between combustion chambers. It occurs due to weak contact pressure due to improper tightening of bolts or overheating of the engine. Signs - violation of the cold start of the engine, the instability of the heated engine.

- Penetration of exhaust gases into the cooling system and heating of antifreeze. Symptoms - air bubbles in the expansion tank, white exhaust, frequent activation of cooling fans.

- Oil entering the cooling system. Symptoms - oil marks in the expansion tank, under the radiator cap.

- Loss of gasket tightness. Appears when improperly installed or temporarily worn. Symptoms are oil stains on the engine.

to contents ↑In addition, the replacement of the rubber gasket has to be done for any repair of the cylinder head, engine or when servicing the timing belt. During installation, sealants are used to improve insulation and enhance the life of the sealant.

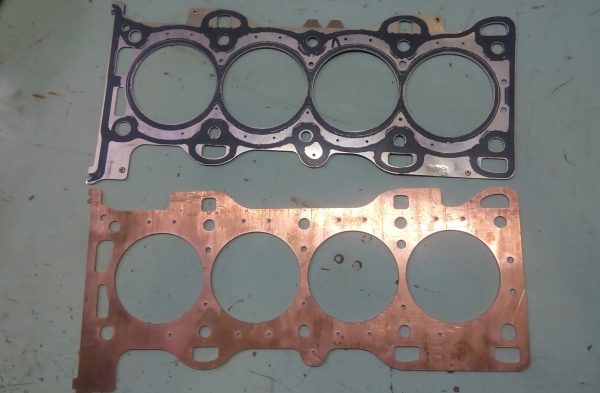

The main types of cylinder head gaskets

The following types of gaskets are used for internal combustion engines:

- Asbestos. Elastic, resilient, withstand high temperatures. To increase strength, they are often reinforced with metal rings. They are inexpensive, but have a number of disadvantages: they do not tolerate vibration, wear out quickly and worsen their sealing properties as they work.

- Asbestos-free. They are used more often than the previous ones, but their price is much more expensive.More resistant to various types of damage, deformation, vibration, designed for continuous operation.

- Metallic and bimetallic. Made of several layers of metal, or additionally contain a sealing elastomer. They are considered the most popular, widely used in modern machines.

Types of sealants

To seal the valve cover, only special means are used - ordinary sealants here will not last long. In composition and properties, they are also not the same:

- Anaerobic. The products are based on the synthetic polymer dimethyl acrylate. Hardening requires anaerobic conditions, i.e. lack of oxygen. Working with such compositions is comfortable for the master - you can apply them slowly, in a convenient mode. The remnants of the funds that crawled out of the seam should be removed immediately - they will still remain semi-liquid and can get into the internal combustion engine.

- Silicone Silicone-based compounds are most often used to seal the valve cover and other components of the car. They are made on the basis of organosilicon compounds, solidify under the action of moisture from the air. In order to securely fasten parts, after application they need to be connected to each other not immediately, but after 5-15 minutes (the sealant needs so much to start setting). Silicone formulations tolerate less accurate application than anaerobic. They can seal quite large gaps and gaps. Another advantage is the chemical inertness of silicone: it does not spoil rubber and any other material, since it does not react with it. To seal the valve cover, it is best to buy a product that is 100% silicone and has no other additives.

- Polyurethane They are characterized by a high degree of adhesion to metal, rubber and other materials. Can be used for fastening parts and sealing them. Durable, flexible, long-lasting, available in different colors, which facilitates application and subsequent removal.

to contents ↑High-quality sealant is able to withstand heat and high pressure, therefore it is well suited for internal combustion engines. A tool of dubious origin can simply dissolve in oil, clog the timing mechanism and cause damage.

Valve Seal Requirements

The main characteristic that the sealant should be on top is heat resistance. A good tool should work at elevated temperatures, and the more heat it can withstand, the better. Other sealant requirements:

- Resistance to chemicals, petrochemicals. The sealant should not deteriorate from aggressive compounds: transmission and engine oils, brake fluid, solvents, antifreeze.

- Tolerance of vibration, mechanical stress, low temperatures. If strength and elasticity are insufficient, the seam will quickly crumble. The sealant must be frost-resistant, because it will have to work in the winter, when the car is in the garage.

- Convenience of application. It is quite difficult to seal the valve cover, so the packaging of the product must be the most comfortable for work. Small spray cartridges have proven best in application, and hard tubes like toothpaste, on the contrary, are uncomfortable.

- Optimal volume. If you only have to seal the valve cover, the minimum amount of sealant will be used up, and there is no point in buying a large package of the product.

to contents ↑You also need to monitor the expiration date - it should be normal, otherwise the sealing properties may decrease.

Overview of popular sealants

To get a really high-quality composition, you should pay attention to the proven brands that are presented in most automotive stores.

Black heat resistant DoneDeal

This sealant is made in the USA, easily withstands operation at –70 ... + 345 degrees. It does not deteriorate from the action of any automotive chemistry, does not evaporate and does not shrink over time, is not afraid of water, does not swell with a stream of air. The tool is suitable for any motors, including those that have oxygen sensors.In addition to the valve cover, the sealant can also be used for pallets of the engine crankcase, gearbox, thermostat housing, cooling system pump, intake manifold. Other advantages of the composition:

- tolerates vibration, shock loads;

- copes with sudden changes in temperature;

- does not provoke corrosion;

- does not crumble, does not crack.

ABRO 11 AB

This sealant is also made in the USA, has a low price with excellent quality. It is used when installing any gaskets, including when replacing the valve cover. It is considered a universal automotive sealant.

Sealant Properties:

- maximum permissible heating - up to +343 degrees;

- resistance to antifreeze, oils, greases, water, brake fluid, antifreeze;

- tolerance of any loads, vibration, shifts due to high elasticity;

- the possibility of applying a thin layer due to a convenient nose.

Victor reinz

Another popular universal solvent-free polyurethane sealant for cars. It is available in two variations - “Rheinzoplast” and “Rheinzosil”, to seal the valve cover you need to use the first (blue). The sealant withstands drops between –50 ... + 300 degrees, resistant to the action of auto chemical goods, aggressive substances. It dries quickly: a thin layer sets in just 15 minutes, and it is possible to install a gasket on it, and it is allowed to start the car after another 30 minutes.

to contents ↑Dirko

Elring Dirco sealant is available in the following modifications:

- Dirko HT. Designed for use at -50 ... + 250 degrees, produced in tubes of 70 ml. Resistant to aggressive substances, mechanical stress.

- Dirko S Profi Press HT. It works at –50 ... + 220 degrees, it is usually used by professionals, as it is presented in bottles of 200 g. Elastic, does not crumble, does not deteriorate from vibration.

- Dirko Spezial-Silikon. Less resistant to the effects of elevated temperatures (operated at -50 ... + 180 degrees), and yet it is used to seal the covers of crankcases and pallets.

It is best to choose the third version of the sealant in a gray package to work with the gasket on the valve cover, because it is famous for its high plasticity and does not deteriorate even when applied to moving parts. After drying, the finished seam easily withstands heavy loads, is resistant to petrochemicals and other aggressive liquids, gases. The tool does not require any time until the rubber gasket is applied. But to seal the valve cover, you can apply all three sealants.

to contents ↑Permatex Anaerobic Gasket Maker Anaerobic Composition

The Permatex sealant belongs to the category of anaerobic - it freezes in an airless environment. It is very thick, it quickly condenses during vulcanization, forming a strong elastic joint, resistant to mechanical stress and vibration. Sealed seam does not deteriorate from the influence of aggressive chemistry, is not afraid of temperature changes, can be operated in the winter. It is realized in small convenient tubes of 50 ml.

CYCLO HI Temp C 952

Silicone auto-sealant quickly seals, glues, provide complete waterproofness, isolates the gasket from the effects of petrochemicals. Maintains flexibility and elasticity over the entire service life. Instantly forms sealed gaskets on engine parts of all types. No additives, only pure 100% silicone. But on sale is very rare.

to contents ↑Curil

The tool with the same name is also produced by Elring in two versions:

- Curil K2. It is used at –40 ... + 200 degrees, it is presented in a tube weighing 75 g with a dispenser. Can seal surfaces with a gap of less than 0.1 mm. It freezes as a result of evaporation of the solvent. In addition to repairing the valve cover, it is designed to work with a fuel and oil pump, injection system, steering gear and other machine components.

- Curil Temperatura. It withstands differences between –40 ... + 250 degrees, is produced in a similar package. Made on the basis of synthetic resins, it does not deteriorate from weak acids, alkalis, water, salts, oils, gasoline and diesel fuel.

Both tools are great for repairing an internal combustion engine.After application, you need to wait about 5 minutes, and only then install the gasket. A thin layer of sealant (less than a millimeter) is recommended.

to contents ↑MANNOL 9914 Gasket maker RED

This silicone sealant works at –50 ... + 300 degrees, it is resistant to sharp temperature drops, as well as to the action of aggressive substances, petrochemicals. It is vulcanized to the state of plastic rubber at room temperature under the influence of water vapor from the air. It creates a reliable gasket that does not crack during service, does not shrink, and does not shift.

to contents ↑Other popular brands

In stores, there are other compositions that can be used in working with the valve cover in order to seal it:

- Loctite 574. An anaerobic compound that hardens at room temperature to form a strong gasket. It is used most often in internal combustion engines, as well as in other nodes where the surfaces are adjacent without a large gap. Heat-resistant, not destroyed by oil.

- Hi-Gear 9041. Sealant based on cermet additives, used for valve cover, eliminating leaks in the cooling system, eliminating cracks in cast-iron or aluminum blocks. It can work under pressure, at constant temperature changes, vibration.

- Anaerobic adhesive for threaded connections. It is widely used in the installation, assembly, repair of automobile and other equipment. It guarantees protection against corrosion, eliminates leaks, strengthens the thread, and withstands differences between –60 ... + 230 degrees.

- Hylomar M. Effectively compacts various automotive components, made on the basis of urethane, which retains elasticity during operation even at extreme temperatures (at –50 ... + 250 degrees). It perfectly aligns joints, is not afraid of fuel combustion products, does not deteriorate from the action of water, oil, grease, kerosene.

How to use valve sealant?

Exact information on the application of the composition is indicated on the packaging, different products have their own characteristics and specifics of application. Sealants of various grades completely harden for a certain period of time: 15-30 minutes are enough for some, others require several hours for complete polymerization. You can not start the car until this time has expired, otherwise the composition will not dry out and gain strength.

to contents ↑Preparation and installation of cylinder head gasket

First you need to make sure that the surface is flat, the cylinder block is not damaged, has no cracks. Before starting installation of the gasket, all technological holes are cleaned and blown with compressed air to clean from dirt and dust. The surface is degreased with a solvent suitable for the vehicle. In the presence of dense pollution they can be removed with an emery cloth or a metal brush.

Next, a small amount of sealant is applied. If there is a lot of composition, when tightening it will fall into the engine. The sealant is extruded into the groove of the lid, smeared, after about 10 minutes a rubber gasket is installed. The bolts are tightened with a torque wrench in a certain sequence (first a preliminary tightening is done, then full).

A sealant when replacing a gasket is a necessary tool that seriously improves the quality of repairs. It is especially needed if a non-original part is used, which may not fit snugly to the surface. In any case, the sealing compound gives a 100% guarantee of reliable service of the unit, if all work on its application was performed correctly.